ISUZU FVR truck-mounted crane is a lifting equipment with excellent performance, safety and reliability. The vehicle is based on the Isuzu FVR heavy-duty chassis and is equipped with an XCMG crane. It adopts an advanced hydraulic system and has the characteristics of high precision and efficiency, and can easily complete various complex lifting operations. At the same time, the hydraulic system also has good stability, which can ensure that the equipment can still maintain efficient working status during long-term use.

Work capacity:

5000 kgTruck model:

PT5050JSQEngine power:

240 HPEngine type:

6HK1-TCLAxle drive:

4×4Gear box:

MLD 6-speed manualRemarks:

XCMG straight boom crane, ISUZU FVR AWD chassisISUZU crane truck, also called ISUZU truck-mounted crane, ISUZU lorry crane, is a special vehicle with a crane installed on a truck chassis, which can easily transport and move heavy objects to various work sites. ISUZU crane trucks are designed to lift and move heavy objects in applications such as construction, utility maintenance and material handling. Cranes are generally divided into straight boom cranes and knuckle boom (articulated) cranes, with lifting capacities ranging from 2 tons to 16 tons, depending on the specific model and configuration. ISUZU truck cranes are often driven by hydraulic systems, allowing for efficient and precise operation. Its versatility makes it suitable for use in different industries such as agriculture, construction, mining and transportation.

The ISUZU truck-mounted crane is an excellent special vehicle that combines the advantages of ISUZU FVR chassis and XCMG crane. This ISUZU crane truck is equipped with an XCMG brand crane, which is a high-quality, high-performance lifting equipment. The crane has excellent lifting capacity and can easily handle heavy lifting tasks. At the same time, the crane adopts advanced technology and structural design, which is stable, safe and easy to operate, improving work efficiency and operating comfort. This ISUZU truck-mounted crane offers outstanding performance and versatility for a wide range of lifting tasks.

Product Specifications

|

General Technical Parameters |

|||

|

Overall Dimension |

8900*2550*3250 (mm) |

||

|

Gross Vehicle Weight |

18000(Kg) |

||

|

Curb Weight |

8200(Kg) |

||

|

Chassis Specification |

|||

|

Chassis Brand |

ISUZU |

||

|

Drive model |

4*2 |

||

|

Cabin |

FVR cabin, Left Hand Drive, with A/C, ABS |

||

|

Number of Passengers |

2 seats with one sleeper |

||

|

Engine |

Model |

6HK1-TCL |

|

|

Type |

4-stroke direct injection , 6-cylinder in-line with water cooling, inter-cooling, turbocharged |

||

|

Power |

177KW/240HP |

||

|

Emission standard |

Euro 5 |

||

|

Displacement |

7790(ml) |

||

|

Fuel type |

Diesel |

||

|

Gearbox |

MLD, 6 Forwards & 1 Reverse, manual |

||

|

Brake System |

Air brake |

||

|

Wheel Base |

5550 mm |

||

|

Front/Rear Axle Loading |

6300/1300(Kg) |

||

|

Approach/Departure Angle |

23/12(°) |

||

|

Overhang |

1250/3545(mm) |

||

|

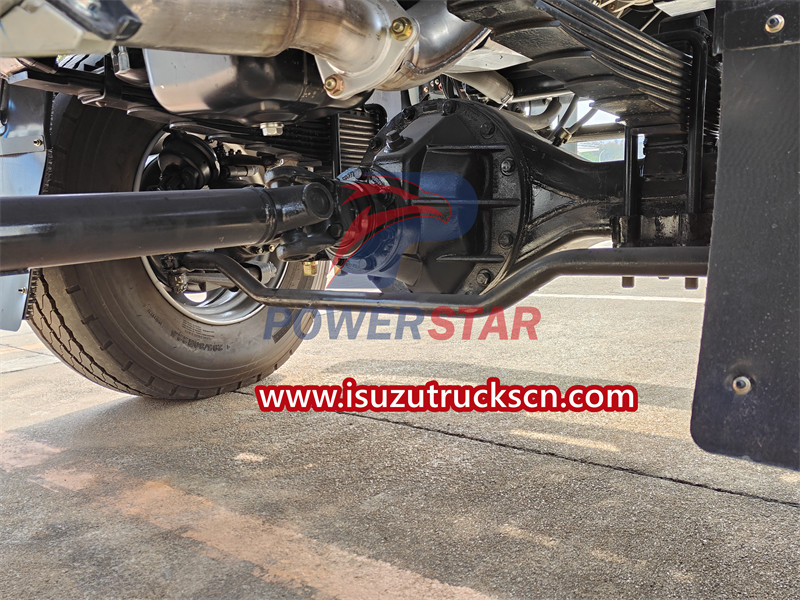

Tire |

295/80R22.5 |

||

|

Number of tires |

6+1 pcs |

||

|

Max Driving Speed |

90(km/h) |

||

|

Superstructure Specifications |

|||

|

Cargo Body |

Dimension |

5600×2300×550(mm) |

|

|

Material |

Q235 carbon steel |

||

|

Cargo Thickness |

Side 1.5mm, Bottom 2.5mm |

||

|

Working System |

Boom Type |

Straight 4-Arm telescopic boom |

|

|

Crane |

Crane Brand |

XCMG |

|

|

Max Lifting Moment |

12.5(T.M) |

||

|

Max Lifting Capacity |

5000(kg) |

||

|

Max lifting height |

11.2 (m) |

||

|

Boom sections |

4 |

||

|

Rotation angle |

360(°) |

||

|

Installation space |

900(mm) |

||

|

Recommend power |

18(kw) |

||

|

Maximum working pressure |

20 (Mpa) |

||

|

Max oil flow |

32 (L/min) |

||

|

Crane weight |

2260(kg) |

||

|

Outriggers |

Type |

H type |

|

|

Span |

2280-5500 (mm) |

||

|

Hydraulic system |

Pressure |

20 (Mpa) |

|

|

Capacity |

90(L) |

||

|

Other Configurations |

PTO, sub-frame, control system on both side, etc. |

||

|

Options |

Remote control, rear outriggers, high altitude seat, load moment Indicator, etc |

||

What are the differences between ISUZU knuckle boom truck and telescopic boom truck?

There are major differences between ISUZU knuckle boom cranes and telescopic boom crane in terms of working principles and applicable scenarios. The specific differences are as follows:

1. Working principle:

• The crane of ISUZU knuckle boom truck consists of multiple hydraulic cylinders forming a joint-like boom connection mechanism, allowing it to complete its movements faster and with higher working power.

• The crane of ISUZU telescopic boom truck uses a set of hoisting mechanisms for retracting and retracting the wire rope. The drum rotates forward to retract the rope, the hook rises, and the revolving hook lowers to release the rope. Its working power is relatively low.

2. Working radius:

• With the same arm length, the telescopic truck crane can expand the working depth and wider working radius by lengthening the wire hook.

• Knuckle cranes are not easy to complete tasks requiring deep work.

3. Applicable scenarios:

• ISUZU knuckle boom trucks are more suitable for smaller working environments such as factory warehouses because their structure requires less space.

• ISUZU telescopic boom crane trucks are more suitable for open working environments because they require more space.

4. Take-off and landing control:

• The telescopic truck-mounted crane adopts a retractable and retractable hoisting mechanism of the wire rope, which can strictly control the lifting and landing of the hoisted object.

• It is difficult to control the vertical takeoff and landing of the lifted object with a knuckle crane because it uses a hydraulic cylinder.

5. Operation difficulty:

• The operation of the ISUZU truck-mounted telescopic crane is relatively simple because it uses a hoisting mechanism to retract and retract the steel wire.

• The operation of ISUZU truck-mounted knuckle cranes is relatively difficult because multiple hydraulic cylinders are required to complete manipulator-like actions.

6. Space occupied:

• The ISUZU truck-mounted knuckle boom crane can shorten the entire boom when transporting goods, occupying relatively less space.

• The boom of a ISUZU truck-mounted telescopic crane can only be placed horizontally, and the vehicle takes up a lot of space when moving.

7. Manufacturing cost:

• The structure of the knuckle boom crane is relatively complex and requires higher precision, so its manufacturing cost is relatively high.

• The structure of the telescopic boom crane is relatively simple and the accuracy requirements are low, so its manufacturing cost is relatively low.

|

|

|

|