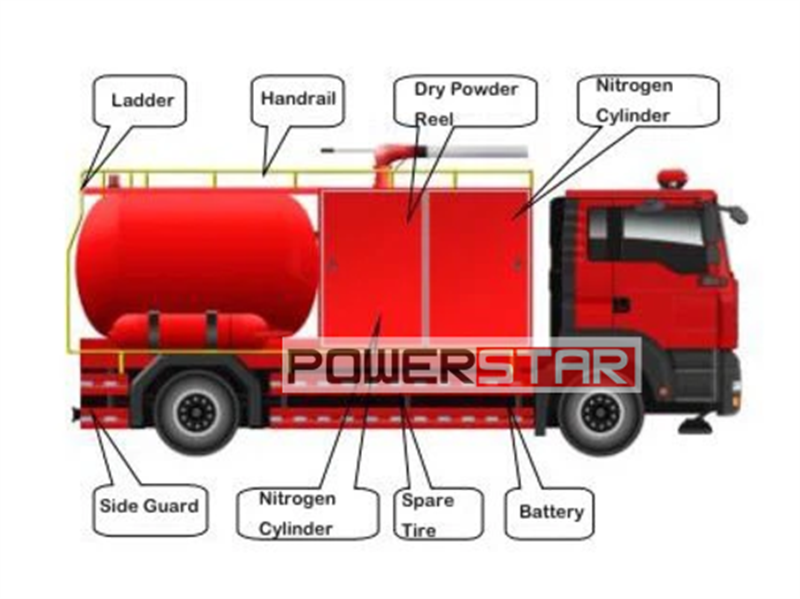

This is a mini water&nitrogen gas fire truck built on the basis of ISUZU NKR Chassis. It is equipped with a powerful ISUZU 4KH1CN6LB engine with a displacement of 2.99L and an output power of 120 horsepower. It adopts a 4X2 drive mode and is equipped with an MSB 5 speed gearbox. The maximum speed can reach 95km/h. It is compact and flexible, and easy to operate to adapt to various complex road conditions. In terms of the fire fighting system, the vehicle is equipped with a 1500-liter carbon steel water tank and 4 80-liter nitrogen cylinders with a design pressure of 1.25MPa. The fire pump is driven by PTO, with a pressure range of 1.6-2.5 MPa and a flow rate of 36L/s. The fire cannon has a spray speed of 32L/s and a range of 45-55 meters, which can effectively deal with various fire situations.

Work capacity:

1500LTruck model:

PT5040NXFEngine power:

120HPEngine type:

4KH1CN6LBAxle drive:

4x2,LHDGear box:

ISUZU MSB 5-speed, with reverseRemarks:

1500L water tank+4 pcs nitrogen gas bottleThis is a mini water&nitrogen gas fire truck built on the basis of ISUZU NKR Chassis. It is equipped with a powerful ISUZU 4KH1CN6LB engine with a displacement of 2.99L and an output power of 120 horsepower. It adopts a 4X2 drive mode and is equipped with an MSB 5 speed gearbox. The maximum speed can reach 95km/h. It is compact and flexible, and easy to operate to adapt to various complex road conditions.

In terms of the fire fighting system, the vehicle is equipped with a 1500-liter carbon steel water tank and 4 80-liter nitrogen cylinders with a design pressure of 1.25MPa. The fire pump is driven by PTO, with a pressure range of 1.6-2.5 MPa and a flow rate of 36L/s. The fire cannon has a spray speed of 32L/s and a range of 45-55 meters, which can effectively deal with various fire situations. The Isuzu NKR fire truck is also equipped with a full set of standard firefighting and rescue equipment, such as shovels, crowbars, axes and cutting equipment, etc., and ladders and floodlights are optional.

Specification:

|

ISUZU NKR water & nitrogen gas fire truck |

|||

|

General |

Vehicle Brand |

Powerstar |

|

|

Chassis Brand |

ISUZU |

||

|

Overall Dimension |

6300*2280*2750mm |

||

|

GWW/ Kerb Weight |

7,500kg/4,220kg |

||

|

Painting |

Red color |

||

|

Cab |

Cab Capacity |

2+4 persons allowed |

|

|

Air Conditioner |

air conditioner |

||

|

Engine |

Fuel Type |

Diesel |

|

|

Engine Brand |

ISUZU engine ,4KH1CN6LB |

||

|

Engine type |

Inline 4-cylinder, turbocharged, inter-cooled diesel engine |

||

|

Power |

120 HP |

||

|

Displacement |

2.99L |

||

|

Emission Standard |

Euro 6 |

||

|

Chassis |

Drive Type |

4X2,left hand drive |

|

|

Transmission |

MSB 6-speed forward, 1 reverse |

||

|

Wheelbase/No.of axle |

3360 mm/2 |

||

|

Tyre Specification |

700 R16 |

||

|

Tyre Number |

6 tyres and 1 spare tyre |

||

|

Max Speed |

95 km/h |

||

|

Fuel tank capacity |

70L |

||

|

PTO |

Full power sandwich type |

||

|

Superstructure |

Water Tank Capacity |

1,500 Litres |

|

|

Tank Material |

carbon steel |

||

|

Nitrogen Gas Bottle |

Air gas flow rate |

≥ 17m3/min |

|

|

Air gas quality |

oil content ≤3ppm, particle content ≤ 3μm |

||

|

Quality |

4 pcs |

||

|

Air gas pressure |

≥ 1.25mpa |

||

|

Compressed air temperature |

ambient temperature +15ºC |

||

|

Nitrogen gas flow rate |

600 m³/hr |

||

|

Nitrogen purity |

(oxygen content 10%) |

||

|

Nitrogen outlet pressure |

1.0MPa |

||

|

Nitrogen gas dew point |

≤ -40ºC |

||

|

Nitrogen gas temperature |

50ºC |

||

|

Ambient temperature |

-30ºC~ +45ºC |

||

|

Explosion proof grade |

no danger |

||

|

Working system |

continuous working |

||

|

Generation time of Nitrogen gas after startup |

≤ 5min |

||

|

Standardized Sub-frame |

Material |

High-strength rectangular tube made of special steel |

|

|

Structure |

Aluminum alloy welded structure. Roof railing with LED light. With aluminum alloy ladder in the rear |

||

|

Fire Pump |

Brand |

China TOP brand |

|

|

Drive mode |

PTO |

||

|

Priming Manner |

Automatic |

||

|

Pressure range |

1.6-2.5 MPa |

||

|

Flow rate |

36L / s |

||

|

Suction Height |

7m |

||

|

Fire Cannon |

Flow speed |

32L /s |

|

|

Range |

45-55 m |

||

|

Superstructure Electric Appliance |

Warning Light and Siren |

Long-row warning light and siren are mounted above cabin. The controller is installed in the driver's cabin. |

|

|

Strobe Light |

Mounted on the both sides of the compartment |

||

|

External Lighting |

LED lights are mounted on the both sides of the compartment |

||

|

Roof Lighting |

LED lights are mounted on the inside of the roof |

||

|

Side Indicator Light |

Inline yellow warning light is mounted on the side of the compartment and pedals |

||

|

All standard accessories.Typical modern fire apparatu scarries equipment for a |

|||

|

Optional |

Ladders,floodlight |

||

Operation:

The working principle of the ISUZU NKR fire truck with nitrogen gas bottle mainly includes the following steps:

1. Start the control system: First, start the control system to put the nitrogen fire truck into standby mode. The control system usually includes electronic components such as LCD screens and programmable logic controllers to realize operations such as fire extinguishing start, nozzle scanning and pipeline protection.

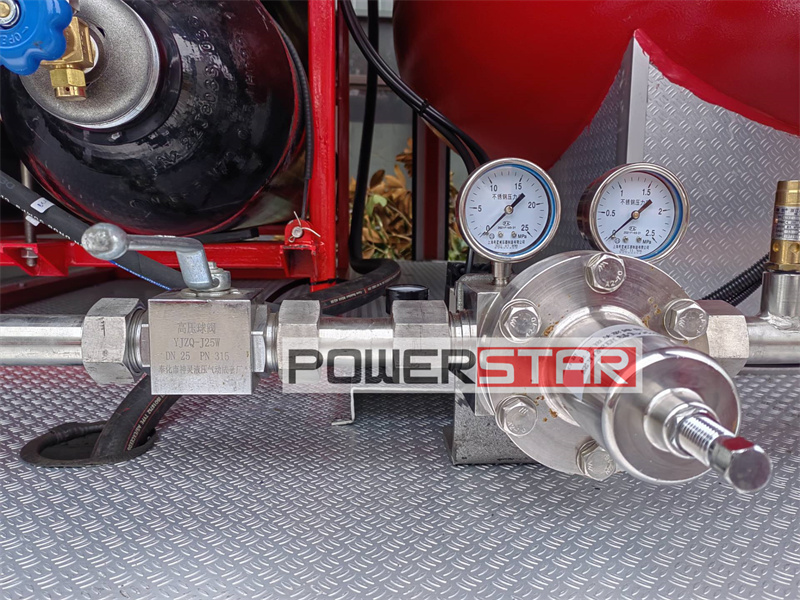

2. High-pressure nitrogen supply: High-pressure nitrogen is stored in nitrogen storage tanks, and the pressure is reduced and the flow is adjusted by the pressure regulation system and the flow regulation system to meet the specific fire extinguishing needs. The pressure regulation system consists of a pressure gauge and a pressure reducing valve to ensure that the nitrogen is released at an appropriate pressure.

3. Nitrogen injection fire extinguishing: When a fire occurs, the control system automatically starts the nozzle system to spray high-pressure nitrogen into the fire area. The rapid injection of nitrogen can reduce the temperature and oxygen concentration at the fire scene, thereby achieving the purpose of fire extinguishing. Since nitrogen is non-flammable, not easy to conduct electricity, and will not damage equipment and objects, it is very suitable for use as a fire extinguishing agent.

4. Completion of the fire extinguishing task: After completing the fire fighting task, the control system automatically shuts down the nozzle system, and the nitrogen fire truck enters standby mode.

Structure:

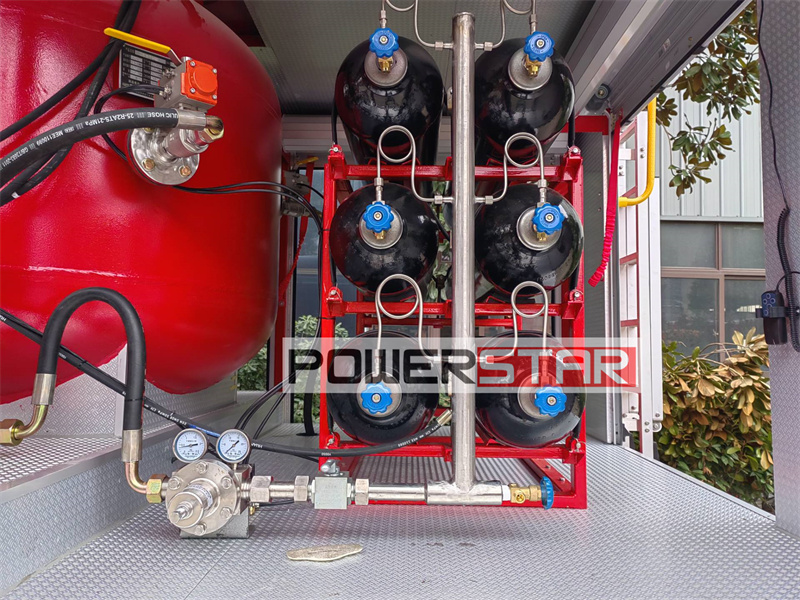

ISUZU NKR Nitrogen fire trucks are mainly composed of nitrogen storage tanks, pressure regulation systems, flow regulation systems, nozzle systems, control systems and other parts:

1. Nitrogen storage tanks: The main storage tanks in nitrogen fire trucks can store high-pressure nitrogen, which is convenient and quick, and automatically solves fire problems through the pressure in the storage tank.

2. Pressure regulation system: It is composed of a pressure gauge and a pressure reducing valve to reduce the pressure of high-pressure nitrogen in the storage tank to meet specific needs.

3. Flow regulation system: According to needs, adjust the flow rate of the fire extinguishing agent and the diffusion of the fire extinguishing agent to give the fire truck flexible fire fighting efficiency.

4. Nozzle system: The nozzle is a component that directly sprays nitrogen during the fire extinguishing process. It is composed of a micro cyclone generator, a regulating valve etc. And can spray different nitrogen flows and pressures as needed.

5. Control system: Using electronic components such as LCD screens and programmable logic controllers, the controller is used to realize operations such as fire extinguishing start, nozzle scanning and protection of pipelines.

Feature:

Advantages and application scenarios of ISUZU fire truck with Nitrogen gas bottle:

1. High efficiency and environmental protection: Nitrogen is non-flammable, not easy to conduct electricity, and will not damage equipment and items.

2. Nitrogen fire trucks are suitable for various types of fires, especially in the fields of electronics, chemical and mechanical industries, as well as places involving flammable and explosive dangerous goods warehouses and storage rooms.