ISUZU truck-mounted crane, also known as ISUZU crane truck, is a kind of engineering equipment that combines a crane and a vehicle. Its design concept is to combine the hoisting function of the crane with the moving function of the vehicle, providing users with an efficient and convenient lifting solution. ISUZU truck-mounted cranes are widely used in construction, logistics, gardening, fire protection and other fields because of their flexibility and practicality.

Work capacity:

5000 kgTruck model:

PT5050JSCEngine power:

240 HPEngine type:

6HK1-TCG61Axle drive:

4×2Gear box:

FAST 8-speed, manualRemarks:

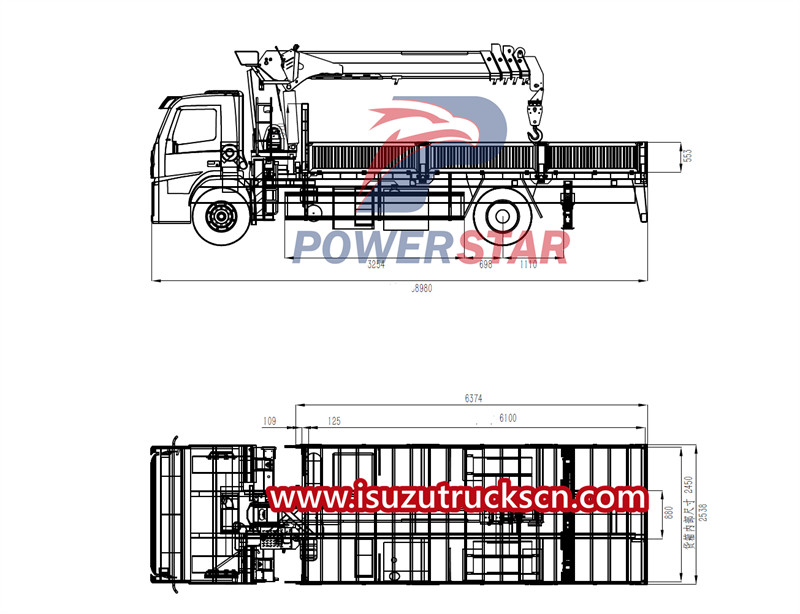

ISUZU FVR heavy duty chassis, XCMG telescopic boom craneISUZU FVR mobile crane truck, also known as a ISUZU FVR truck with crane, ISUZU FVR boom crane truck, ISUZU FVR truck-mounted crane, is a special transportation device that combines a truck-mounted crane with a chassis. The main components of a ISUZU mobile crane truck include the boom, lifting torque, outriggers and cargo box. The boom is the main working part of the ISUZU truck-mounted crane and is responsible for lifting and moving heavy objects. Lifting moment refers to the product of the length of the boom and its maximum lifting weight. The greater the torque, the stronger the lifting capacity of the ISUZU crane truck. The outriggers play a stabilizing role when lifting weight and prevent the equipment from tipping over. The cargo box is one of the important components of the ISUZU boom crane truck and is mainly used to load goods that need to be hoisted. The size and shape of the cargo box will be designed according to actual needs to better adapt to the loading of various goods.

As the core part of ISUZU FVR mobile crane truck, the crane directly affects the lifting capacity of the vehicle. This Isuzu truck-mounted crane is equipped with a well-known Chinese brand XCMG crane, which mainly consists of the following parts:

1. Boom: The starting part of the hoisting system is the boom, which is usually a telescopic and rotating boom structure. The boom has sufficient strength and rigidity to support the weight of the hoisted items. According to the operation requirements, the length of the boom can be adjusted to adapt to lifting operations of different heights.

2. Pulleys and wire ropes: Pulleys and wire ropes are important transmission components in the hoisting system. One end of the wire rope is fixed to the pulley and the other end is connected to the hook. When the hydraulic motor drives the pulley to rotate, the wire rope will be tightened or relaxed, thereby raising and lowering the hook. By changing the magnification of the pulley, the tension of the wire rope can be adjusted to adapt to items of different weights.

3. Control and operating system: The control system of the Isuzu FVR truck-mounted crane is responsible for receiving the operator's instructions and converting them into movements of the hoisting system. The operator controls the telescoping and rotation of the boom, as well as the lifting and lowering of the hook, through control handles, buttons or automatic control systems. Sensors and limit switches in the control system can detect the position and status of the hoisting system to ensure the accuracy and safety of the operation.

4. Auxiliary devices: In addition to the main transmission components, the hoisting system also includes some auxiliary devices, such as balance valves, safety locks, buffers, etc. These devices can enhance the stability and safety of the hoisting system and prevent overloading, accidental falls, etc.

Product Specifications

|

General Technical Parameters |

|||

|

Overall Dimension |

9040*2590*3560 (mm) |

||

|

Gross Vehicle Weight |

18000(Kg) |

||

|

Curb Weight |

7800(Kg) |

||

|

Chassis Specification |

|||

|

Chassis Brand |

ISUZU |

||

|

Drive model |

4*2 |

||

|

Cabin |

GIGA cabin, Left Hand Driving, with air conditional |

||

|

Number of Passengers |

2 seats with one sleeper |

||

|

Engine |

Model |

4-stroke direct injection , 6-cylinder in-line with water cooling, inter-cooling, turbocharged |

|

|

Power |

177KW/240HP |

||

|

Emission standard |

Euro 6 |

||

|

Displacement |

7790(ml) |

||

|

Fuel type |

Diesel |

||

|

Gearbox |

FAST, 8 Forwards & 1 Reverse, manual |

||

|

Brake System |

Air break |

||

|

Wheel Base |

5550 mm |

||

|

Front/Rear Axle Loading |

6300/1300(Kg) |

||

|

Approach/Departure Angle |

23/12(°) |

||

|

Overhang |

1250/3545(mm) |

||

|

Tire |

295/80R22.5 |

||

|

Number of tires |

6+1 pcs |

||

|

Max Driving Speed |

90(km/h) |

||

|

Superstructure Specifications |

|||

|

Cargo Body |

Dimension |

5600×2300×550(mm) |

|

|

Material |

Q235 carbon steel |

||

|

Cargo Thickness |

Side 1.5mm, Bottom 2.5mm |

||

|

Working System |

Boom Type |

Straight 4-Arm telescopic boom |

|

|

Crane |

Crane Brand |

XCMG |

|

|

Max Lifting Moment |

12.5(T.M) |

||

|

Max Lifting Capacity |

5000(kg) |

||

|

Max lifting height |

11.2 (m) |

||

|

Boom sections |

4 |

||

|

Rotation angle |

360(°) |

||

|

Installation space |

900(mm) |

||

|

Recommend power |

18(kw) |

||

|

Maximum working pressure |

20 (Mpa) |

||

|

Max oil flow |

32 (L/min) |

||

|

Crane weight |

2260(kg) |

||

|

Oil tank capacity |

900(L) |

||

|

Outriggers |

Type |

H type |

|

|

Span |

2280-5500 (mm) |

||

|

Hydraulic system |

Pressure |

20 (Mpa) |

|

|

Capacity |

90(L) |

||

|

Other Configurations |

PTO, sub-frame, control system on both side, etc. |

||

|

Options |

Remote control, rear outriggers, high altitude seat, load moment Indicator, etc |

||

Isuzu FVR mobile crane truck is a high-performance engineering equipment with the following performance characteristics:

1. Powerful hoisting capacity: Isuzu FVR mobile crane truck is equipped with XCMG crane, which has an advanced hoisting system and can carry out large-tonnage hoisting operations. Its powerful lifting capabilities enable users to complete various engineering tasks more efficiently.

2. High stability: Isuzu FVR truck with crane adopts high-quality materials and structure, which has excellent stability and safety. During hoisting operations, it can ensure the smooth operation of the equipment and prevent shaking and overturning, thereby ensuring the safety of the operation.

3. Quick response: The transmission system and control system of the Isuzu FVR mobile crane truck are very advanced, allowing the equipment to respond quickly when performing hoisting operations. This can improve work efficiency and shorten operation time, thus bringing greater economic benefits to users.

4. Easy to operate and maintain: The design of the Isuzu FVR truck-mounted crane fully takes into account the needs of users. Its operation is simple and easy to understand, and the maintenance and upkeep of the equipment is also very convenient. This can reduce users' operating and maintenance costs and improve equipment utilization.

5. Strong adaptability: Isuzu FVR mobile crane truck is suitable for various working environments and conditions.

Safety precautions for operating ISUZU FVR truck-mounted crane

1. Ensure site safety

Before operating the ISUZU truck-mounted crane, the safety of the work site must be ensured. Check the site for obstacles, hazardous materials or other safety hazards and ensure the work area is clear. If necessary, set up safety warning signs and isolation measures.

2. Check the condition of the equipment

Before using the ISUZU FVR mobile crane truck, be sure to conduct a complete inspection of the equipment. Check whether all components, such as wire ropes, pulleys, hooks, etc., are normal, intact, and not aging. If there is any problem, it should be repaired or replaced in time.

3. Follow operating procedures

When operating ISUZU FVR truck with crane, operating procedures and safety technical requirements must be strictly observed. It is not allowed to be overloaded, and it is strictly prohibited to disassemble or modify equipment parts at will. Follow correct lifting, moving and placement procedures to avoid accidents caused by improper operation.

4. Pay attention to wind and weather

When operating ISUZU FVR boom crane truck, pay close attention to wind and weather changes. In severe weather such as strong winds, lightning, and heavy rain, operations should be stopped immediately and corresponding safety measures should be taken. Under strong wind conditions, special attention should be paid to the stability of hanging objects to prevent them from being blown by the wind.

5. Reasonably choose the lifting method

Choose the appropriate lifting method according to different situations, including using single rope or double rope, fixed lifting or mobile lifting, etc. Make sure the chosen method meets safety requirements and can effectively complete the lifting task.

6. Avoid overloading and unbalanced loading

The ISUZU moible crane truck has clear load limits and must not be overloaded. According to the weight and characteristics of the hoisted items, the wire ropes and hooks should be reasonably configured to prevent breakage or overturning accidents caused by unbalanced or overloaded loads.

7. Pay attention to heights and surroundings

When operating ISUZU boom crane, you should always pay attention to changes in height and surrounding environment. Avoid working in dangerous areas such as high-voltage lines, flammable and explosive areas, and ensure a safe distance from other objects. During the movement, pay close attention to surrounding obstacles and human activities to ensure safety.

8. Maintain communication with command staff

When performing hoisting operations, operators should maintain close communication with the commander to ensure that the hoisting process is coordinated. Follow the instructions of the commander and do not act without authorization or perform risky operations.

9. Regular maintenance and upkeep of equipment

In order to ensure the normal operation and extend the service life of the ISUZU mobile crane truck, regular maintenance and upkeep must be carried out. Check the wear, looseness and corrosion of each component in accordance with regulations, and repair or replace them in a timely manner. Keep equipment clean and protected from dirt and rust.