The ISUZU mini refueling truck is a convenient and flexible refueling equipment suitable for various places and occasions, such as construction sites, road maintenance, oil exploration, etc. The device has the characteristics of mobility, portability and efficiency, and can meet the needs of different users.

Work capacity:

5000 LitersTruck model:

PT5050GJYEngine power:

98 HPEngine type:

4KH1CN5LSAxle drive:

4×2Gear box:

MSB 5-speed, manualRemarks:

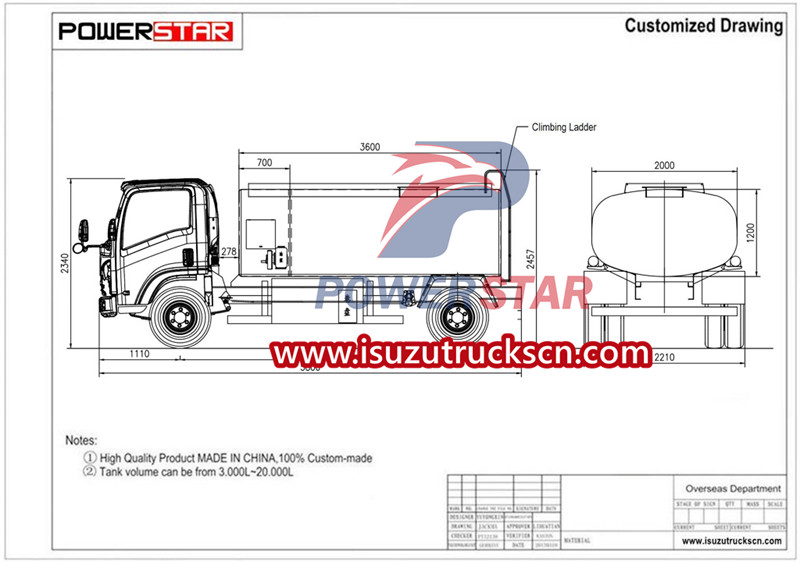

Costomized tanker dimension, equipped with refueling machine

The Isuzu oil tanker lorry is a vehicle specially used to transport oil products. Its design fully takes into account the characteristics of the oil products and safety issues during transportation. The oil tank truck mainly consists of the following parts:

1. Tank body: The tank body is the main part of the ISUZU oil tank truck, usually made of carbon steel or stainless steel, and has a cylindrical shape. The inside of the tank is usually coated with an anti-corrosion coating to increase its service life.

2. Head: The head is the end of the tank, usually round or oval. The main function of the head is to seal the tank and prevent oil leakage. The head is generally manufactured according to pressure vessel standards and has a certain thickness and strength.

3. European standard manhole cover: The manhole cover is one of the important safety devices of the ISUZU oil tanker lorry. Its main function is to realize the overflow prevention and emergency explosion-proof functions of the oil tanker. It is usually installed on the top of the tank truck to prevent oil leakage and can withstand a certain amount of pressure and impact. The manhole cover is also equipped with a built-in breathing valve, which can automatically adjust the pressure in the tank to prevent the pressure in the tank from being too high or too low.

4. Refueling device: The refueling device is an important part of ISUZU fuel tanker truck, including the refueling port, refueling pipe and quick connector. The refueling port is located on the upper part of the tank for easy filling of oil. The refueling pipe and quick connector are used to connect the oil pump and refueling gun to achieve quick and convenient refueling operations.

5. Oil pump: The oil pump is one of the important parts of ISUZU fuel bowser. Its function is to extract the oil in the tank and transport it to the destination. The oil pump is usually installed at the bottom of the tank, which can make full use of the gravity of the oil and reduce the power consumption of the pump.

6. Liquid level gauge: The liquid level gauge is an instrument used to measure the oil level in the tank. Through the liquid level gauge, the driver can know the amount of oil in the tank at any time to ensure transportation safety. Commonly used liquid level gauges include float level gauges, magnetic flap level gauges, etc.

7. Safety valve: The safety valve is one of the important safety devices of ISUZU diesel bowser. Its function is to automatically open when the pressure in the tank is too high, release the pressure and prevent the tank from rupture. Safety valves are usually installed on the top of the tank.

8. Connecting pipe: Connecting pipe is a pipe used to connect various components, such as inlet and outlet oil pipes, exhaust pipes, etc. The connecting pipe is made of pressure-resistant and corrosion-resistant materials to ensure the safety of the oil during transportation.

Product Specifications

|

Vehicle Technical Parameters |

|

|

Gross Vehicle Weight (Kg) |

7300 |

|

Curb Weight (Kg) |

3850 |

|

Overall Dimensions (mm) |

5995×2100×2400 |

|

Tank Volume (L) |

5000 |

|

Tank Thickness(mm) |

4 |

|

Tank Body Material |

Q235 Carbon Steel |

|

Anti wave plate |

Standard |

|

Operating Temperature(°C) |

-20~45 |

|

Manhole cover |

European standard |

|

Emergency shutoff valve |

Factory standard |

|

Oil gas recovery unit |

Factory standard |

|

Anti-overflow alarm device |

Factory standard |

|

Fuel loading method |

Bottom filling |

|

Gear oil pump flow(m³/h) |

30 |

|

Toolbox |

Customized to your needs |

|

Maximum Speed(km/h) |

80 |

|

Chassis Technical Parameters |

|

|

Brand |

ISUZU |

|

Type of fuel |

Diesel |

|

Engine Power(KW/HP) |

72/98 |

|

Brake |

Air brake |

|

Front Axle/Rear Axle(t) |

2.5/4.8 |

|

Gearbox |

5 Speed Manual |

|

Number of Axles |

2 |

|

Wheelbase (mm) |

3360 |

|

Number of Tires |

6 |

|

Tyre Specification |

7.00R16 |

The functions of the manhole cover and breathing valve of ISUZU mini oil tanker lorry:

The manhole cover and breathing valve of ISUZU oil tanker realize the function of automatically adjusting the pressure inside the tank through certain structures and principles.

Manhole covers are usually equipped with a built-in breathing valve, which has the function of automatic pressure adjustment. When the pressure in the tank is higher than a certain value, the breathing valve will automatically open to release part of the pressure to keep the pressure in the tank within a safe range. Similarly, when the pressure outside the tank is higher than the pressure inside the tank, the breathing valve will automatically close to prevent external air from entering the tank and ensure that the oil is not oxidized and contaminated.

This automatic adjustment function relies on springs and pressure-sensitive components inside the breathing valve. When a pressure difference occurs between the inside and outside of the tank, the sensitive element will sense the pressure change and push the valve core to move, thereby opening or closing the breathing valve. Through this mechanism, the manhole cover and breathing valve can automatically adjust the pressure inside the tank to ensure the transportation safety of ISUZU oil bowser trucks.

It should be noted that during use of the tank truck, the status of the manhole cover and breathing valve must be regularly checked to ensure their normal operation and good sealing performance. At the same time, relevant regulations and standards must be followed for the use and maintenance of ISUZU oil tank trucks to maximize the safety and transportation efficiency of tank trucks.