ISUZU NKR fuel bowser, Isuzu 4KH1CN diesel engine with 120HP, MSB 5 shift manual gearbox with 6 forward and 1 reverse back, 235/75R17.5 tubeless tires with 6+1 pcs, durable quality and performance, 5000liters cabon steel material fuel tanker with thickness 5mm, internal with antistatic coating for safety transportation. The Isuzu NKR refueling truck fuel dispenser equipped at back of the fuel bowser, matched with 22m refueling hose reel, painting and logos as customized. Call me today to get quotation today.

Work capacity:

5000 LitersTruck model:

PT5070GJY05KEngine power:

120 hpEngine type:

4KH1CNAxle drive:

4×2Gear box:

MSB 5-speed, manualRemarks:

Japanese ISUZU NKR truck chassis, Fuel dispenser 20m hose reel

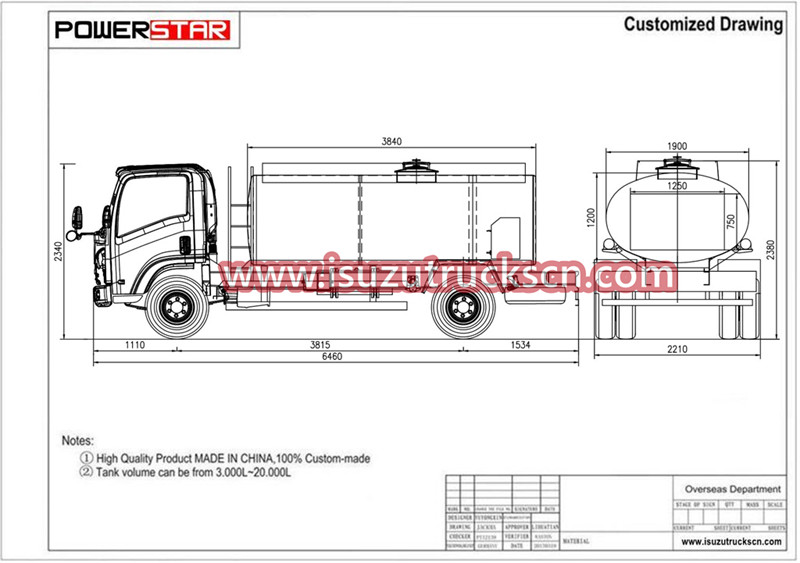

Isuzu Fuel Truck based on type II ISUZU 4*2 Left Hand Drive chassis, Isuzu NKR refueling truck with Fuel tanker capacity could up to 5,000liters, which also installed with top quality refueling gun and pipeline reel, mainly used for Fuel storage, transportation and refueling, and the working aerial can be city street, factory, desert areas and other areas of need. The Isuzu fuel truck designed to fully rely on the advantages of the original of ISUZU brand chassis, fully consider the product's convenience and reliability, also the chassis ISUZU technology features. The Isuzu fuel truck tanker material is international standard carbon steel, both internal and external with anti-rust and anti-static painting, which can effective to avoid rusting. As for tank capacity, this is strictly 5CBM and safety enough to transport & refueling oil based on customer requirement.

The ISUZU Nkr Fuel Tanker Truck equipped with 20m pipeline hose reel and refueling gun, rear climbing ladder, Euro standard Manhole, top & side & rear guard plate and safety fuel inlet & outlet valves to help better use of the trucks. Cab for the single-row Comfortable seat, nice driving feeling. Therefore, the vehicle is an ideal Fuel Tanker Truck mainly for oil transportation & refueling function

Product Parameters:

| Isuzu NKR Refueling Truck | |

| Product Name | isuzu 600p fuel tank truck 5000L |

| Driving Type | 4×2,Left hand drive |

| Weights | |

| Related weight (kg) | 5000 |

| Curb weight(kg) | 3365 |

| Dimensions | |

| Wheelbase(mm) | 3360 |

| Overall Dimension(mm) | 5990×1960×2400 |

| Box dimension | 5000liters |

| Max speed(km/h) | 90 |

| Engine | |

| Engine model | 120HP |

| Engine type | 4 stroke water-cooled,inter-cooling |

| No. of cylinders | straight-4 cylinders |

| Displacement(L) | 2999L |

| Max. output (kw) | 88kw |

| Drive Line | |

| Transmission | 5 forwards,1 reverse gear,manual operation |

| Steering | With power steering |

| Axle | |

| Front axle | 2.5 tons |

| Rear axle | 4.8tons |

| Tire specification | |

| Tire specification | 7.00R16 standard tire,6 tires+1 spare tire |

| Specification of fuel tanker | |

| Tanker shape | Ellipse water tanker |

| Tanker material | Q235,carbon steel,4mm |

| Manhole | Man way access hole on top of tank;1 units DN500mm manhole |

| Horse reels | Two 75 ft hose reels at each side of the truck |

| Standard configuration | With pump |

| optional | compartments,sea valve,bottom loading,flow meter,european manhole,oil vapor recovery, |

| fuel dispenser | |

| flowmeter | |

The Isuzu fuel tanker trucks pipeline system is simple but very practical. One main pipeline connect with fuel tank and fuel pump, which means there are two ways to collection water: firstly is pumping fuel directly through Fuel pump; secondly is collection fuel from top Manhole. The ISUZU Fuel Truck makes use of the special power take off (PTO) to get power from the engine, and then transfer the power to the Fuel Pump via drive axle so to rotate the pump. The fuel pump, pipelines, valves and joints consist of the pipeline system. Turn on / off valves through the regulated program, the pump can absorb fuel into the tank, also can pumping-out the fuel. As for the 20m refueling pipeline with gun and reel, this can be used refueling all trucks through the special gun. And then come to all function.

How to operate the Isuzu fuel truck:

1. The Schedule of Pumping-In Course: open Fuel Pump In Ball Valve 2, close Fuel Pump Out Ball Valve 1 & 3, and the spot of Three-Way Ball Valve pointing to C (Means the Three-Way Ball Valve A & B Opened), close the Ball Valve 4 (which connect the Refueling pipeline with gun and reel), open the Submarine Emergency Valve. Then oil sucked into the pump through Fuel Pump In Ball Valve 2 under negative pressure of fuel pump, then into the fuel tank. Details showing as above chart.

2. The Schedule of Pumping-Out Course:

Not Through the Pointer Flowmeter--Make sure the Fuel Pump Out Ball Valve 1 open; Fuel Pump Out Ball Valve 3 and Fuel Pump In Ball Valve 2 closed, and the spot of Three-Way Ball Valve pointing to B (Means the Three-Way Ball Valve A & C Opened), close the Ball Valve 4 (which connect the Refueling pipeline & Gun), open the Submarine Emergency Valve. Then oil pumping-out the fuel pump through Submarine Emergency Valve under negative pressure of fuel pump, then out of the fuel tank through Fuel Pump Out Ball Valve 1.

Through the Pointer Flowmeter-- Make sure the Fuel Pump Out Ball Valve 3 open; Fuel Pump Out Ball Valve 1 and Fuel Pump In Ball Valve 2 closed, and the spot of Three-Way Ball Valve pointing to B (Means the Three-Way Ball Valve A & C Opened), close the Ball Valve 4 (which connect the Refueling pipeline & Gun), open the Submarine Emergency Valve. Then oil pumping-out the fuel pump through Submarine Emergency Valve under negative pressure of fuel pump, then out of the fuel tank through Fuel Pump Out Ball Valve 3. The Flowmeter can calculate the flow rate and quantity.

3. The Schedule of Refueling Course: close Fuel Pump Out Ball Valve 1 & 3 and Fuel Pump In Ball Valve 2, and the spot of Three-Way Ball Valve pointing to B (Means the Three-Way Ball Valve A & C Opened), open the Ball Valve 4 (which connect the Refueling pipeline & Gun), open the Submarine Emergency Valve. Then oil can through Flowmeter to record the capacity and can be pumping-into the Refueling Pipeline with Gun under pressure of fuel pump. Then you can operate the Fuel Dispenser to refuel all trucks.