Work capacity:

5CBMTruck model:

PT5050ZYSEngine power:

130HPEngine type:

4KH1CN5HSAxle drive:

4×4Gear box:

Manual, 5-speedRemarks:

Semi-sealed bucket as required. Title device is optionalThe NKR rear loader garbage truck is a special sanitation vehicle used for garbage collection and transfer. The vehicle is equipped with a sealed compartment, filler (tailgate), push blade, hydraulic system and electrical control system. The garbage is poured into the loader at the rear of the truck and is crushed, compressed and pushed into the compartment, so the loading capacity is larger than that of ordinary garbage trucks. When loading and unloading garbage, it does not pollute the environment and reduces the labor intensity of cleaning workers. The waste compactor trucks produced by our company adopt computer-controlled automatic operating devices and have a high degree of automation.

The compactor body and filler of the NKR refuse compactor truck are made of high-quality carbon steel plate welded structures, and it adopts an arc-shaped section. There is a folding shovel driven by a hydraulic cylinder inside the box, which can slide along the guide rails on both sides of the bottom of the compactor body. The push shovel not only functions to unload garbage, but also seals the front end of the compactor. The filler has a sliding plate and a scraper, which are also driven by the cylinders. The sliding plate moves in the chute on both sides of the filling device, and the scraping plate moves around the hinge axis of the sliding plate. A lifting cylinder and a locking mechanism are installed between the compactor body and the filler. The lifting cylinder drives the filler to lift and lower, and the locking mechanism locks the filler on the compactor. The bucket turning mechanism at the rear of the vehicle realizes the flipping and dumping of garbage and return of the trash bucket through the oil cylinder. The hydraulic system adopts a combined control valve group, and the oil pipes are neatly arranged, beautiful and reasonably laid out.

Vehicle Parameters

Vehicle Description

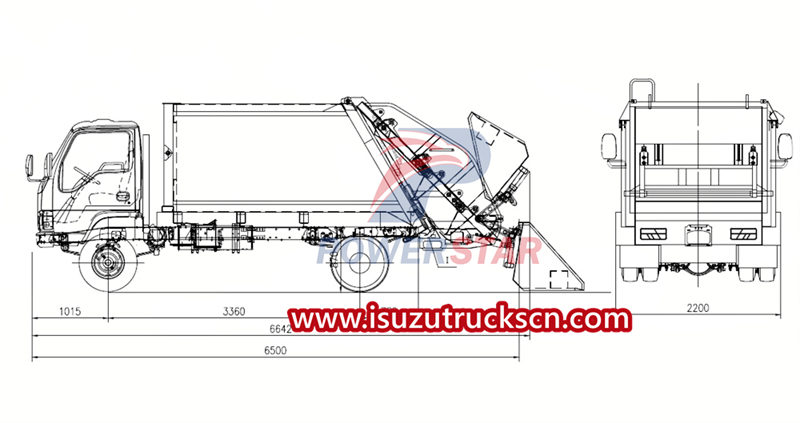

Overall dimensions

6500*2200*2650mm

GVW

7300kg

Curb weight

5400kg

Chassis brand

ISUZU

Driving type

4*2, left hand drive

Chassis Description

Chassis model

QL1070A

Cab

ISUZU 600P single

cabin, A/C

Wheelbase

3360mm

Tire specification

7.00RR16

Tire quantity

6+1 units

Engine

Engine model

4KH1CN5HS

Emission standard

Euro 5

Power

130HP

Displacement

3 L

Gear box

Model

MSB

Number of gears

5 forward gears& 1

reverse

Brake system

Oil brake

Axle

Front

2.5T

Rear

4.8T

Suspension

Front

8- Leaf spring

Rear

6+5-Leaf spring

Fuel tanker

Type

Iron fuel tank, with

lockable cap

Capacity

100 L

Compactor body description

Volume

5cbm

Material

T420 steel

Compaction ration

1:3.5

Loading cycle

25~30s

Unloading cycle

15~20s

Control system

Electrically Controlled

Hydraulic + Manual Hydraulic

Compactor type

Two-way, push in the front,

compressor in the back

Standard equipment

Equipped with garbage

tanker, push shovel, hydraulic transmission system, electrical controlling

system.

ISUZU NKR trash compactor truck maintenance precautions

1. The use and maintenance of the chassis and engine parts of the vehicle shall be carried out in accordance with the provisions of the chassis vehicle instruction manual.

2. During the run-in stage of a new vehicle, the driving mileage is between 1,500-2,500km and the box is lifted (push plate) and unloaded within 900 times. The loading capacity is 70% of the rated load mass. Do not step on the accelerator sharply when unloading.

3. After the hydraulic cylinder has worked 300 times, all working oil should be replaced. Unscrew the oil drain plug of the hydraulic oil tank, then inject new oil from the upper oil filling hole, then start the engine and test run each cylinder twice to confirm that it works reliably.

4. High-pressure oil pipes should be replaced regularly every two years. If cracks, damage, expansion, etc. are found during use, they should be replaced in time.

5. Check the oil leakage of the hydraulic system frequently, and repair and replace the oil seal in time.

6. Lubrication uses general automotive potassium-based grease (GB5671-85).

7. Clean the entire vehicle, compactor body, and inner surface of the pressure filler after each day's work. Check the hydraulic oil inventory frequently, add lubricating oil to each moving part regularly, and apply lubricating oil to the surface of each guide rail.

8. Regularly check and adjust the working pressure of the gear oil pump; check the oil filter element, remove surface impurities or replace the filter element; regularly replace the hydraulic oil.