ISUZU Elf 6 Wheelers 4cbm Sewer Sludge Tank 6 Cubic Meter Vacuum Truck Hot Sale for Philippines Market. Isuzu mini NKR truck chassis mounted with 4KH1 diesel engine with 120HP and 2999cc emission. The 6000L sewage tanker with round shape or oval shape, high strength steel with thickness 6mm. As for accessory of sewage suction function: Equipped with PTO, transmission shaft, vacuum suction sewage pump, high pressure molding tank, moisture separator, gas-oil separation, multiple directional control valve, hanger rod, self-discharging valve, suck fecal gun and pipe network system, also on top mounte with adjustable suction hose, painting and logos can be customized.

Work capacity:

6000 LitersTruck model:

PT5070GXWEngine power:

120 HPEngine type:

4KH1CNAxle drive:

4×2Gear box:

MSB 5-speed manualRemarks:

Adjustable on top Suction Hose with 7m pipeline

POWERSTAR TRUCKS produced and export ISUZU NKR sewage suction truck is a special vehicle designed for the sanitation field, and Isuzu sewage truck is widely used in sewage cleaning and sewage pumping in urban environments. Built on Isuzu's NKR chassis, the Isuzu NKR vacuum tank truck offers outstanding performance and reliability and Isuzu cesspit emptier truck is widely recognized as a powerful tool for efficiently treating sewage and wastewater. Moreover, the ISUZU NKR sewage tank truck is equipped with a powerful sewage suction system, and optional to be Italy brand vacuum pump as MORO, JUROP, BP, that can quickly absorb and discharge sewage. Isuzu NKR sewer truck vacuum pump system has a high suction power and can efficiently handle all types of liquid waste, including sewage, mud, etc. This makes the Isuzu cesspool suction trucks play an important role in urban road cleaning, sewage treatment and emergency leakage handling.

| Isuzu cesspit emptier Tanker Description | ||

| Tanker | Capacity | 6000 Liters |

| Material | 6mm thickness, high quality carbon steel | |

| Structure | Welding, vacuum tank, Cylindrical | |

| Pump | Type | Vacuum pump |

| Flux | 68(L/S) | |

| Rating speed | 800~1000(r/min) | |

| Shaft power | 5(kw) | |

| Features | Low speed, low fuel consumption, low noise, high vacuum, high efficiency | |

| Manufacture | Hangzhou WEILONG Pump Co., Ltd. | |

| Pipe | Suction and discharge pipe | |

| Special function | Suction time ≤ 5min, effective suction range ≥ 8, Max vacuum degree ≤ 15 Kpa, dump angle ≥ 45 |

|

| Standard configuration | Equipped with Inspect window,discharge valve,cleaning apparatus,5 meter long suction pipe,oil-water separators, overflow valve,etc. Cylinder vacuum tank can be lifted hydraulically to 40-45 degree. Rear door can be opened and closed hydraulically. |

|

| Optional configuration | Tanker material: stainless steel. Vacuum pump : Italy or Spain vacuum pumps. Anti-rust coating inside tank |

|

| Isuzu NKR truck Chassis Description | ||

| Chassis model | QL1070 | |

| Steering | LHD | |

| Cab | 100P / mini ELF / NKR, single row, with A/C | |

| Wheelbase | 3360mm | |

| Tire specification | 7.00R16 | |

| Tire quantity | 6 tires and 1 spare tire | |

| Engine | Engine model | 4KH1CN |

| Emission level | EURO 5/6 | |

| Displacement/output | 2999ml/88kw | |

| Horse power | 120HP | |

| Gear box | Model | ISUZU MSB |

| Number of gears | 5-speed | |

| Brake system | Air break | |

| Axle | Front | 2.5T |

| Rear | 4.8T | |

| Fuel tanker | Type | Durable Carbon Steel |

| Capacity | 76L | |

| Isuzu NKR vacuum tank truck Description | |

| Overall dimensions | 6500*2300*2850mm |

| GVW | 7300kg |

| Curb weight | 3800kg |

| Chassis brand | ISUZU |

| Traction type | 4*2 |

During the entire suction and discharge process, the Isuzu vacuum tanker pump truck adopts an efficient and reliable hydraulic system to ensure the safety and reliability of operation. The tank can be lifted, lowered and turned over by the hydraulic system to facilitate cleaning and discharge of sewage. Isuzu NKR Vacuum Tank Truck is used for removing and transporting sand, stones, grease, sludge and other debris from sewage pipelines and / or sanitary sewer by vacuum suction pump. Isuzu sewer trucks also could provide efficient solution to industrial vacuum requirement . Hydraulic system and pneumatic components could be added to fulfill the requirements of specific operations.

ISUZU NKR fecal sewage suction truck is a special vehicle produced and supply by POWERSTAR. Which is specially used for urban sanitation and sewage treatment. Isuzu sewage truck is mainly used to clean feces and sewage in urban sewage pipes, septic tanks, sewage tanks and other places. The structure and usage of Isuzu septic pump trucks will be introduced in detail below:

Chassis structure: ISUZU NKR fecal suction truck usually adopts Isuzu NKR/600P truck chassis, which has a strong and durable frame structure and is adaptable to various roads and environments, equipped with 4KH1CN diesel engine, 120HP and 2999L emission.

Sewage suction system: The Isuzu sewer tanker truck is equipped with a super powerful vacuum pump and suction pipe to absorb feces and sewage and store them in a dedicated liquid storage tank, and the customized top suction hose is adjustable to meet all requirements.

Liquid storage tank: There is a specially designed liquid storage tank at the rear of the Isuzu cargo truck to store the sucked feces and sewage, so to ensure that there will be no leakage during transportation, tanker material is carbon steel, with thickness can be up to 6mm.

Control system: Equipped with an operation console, the operator can control the start and stop of the vacuum pump, pump brand can be Chinese brand or original Italy brand MORO, BP, JUROP, etc. Monitor the sewage suction process and other operations through the control system.

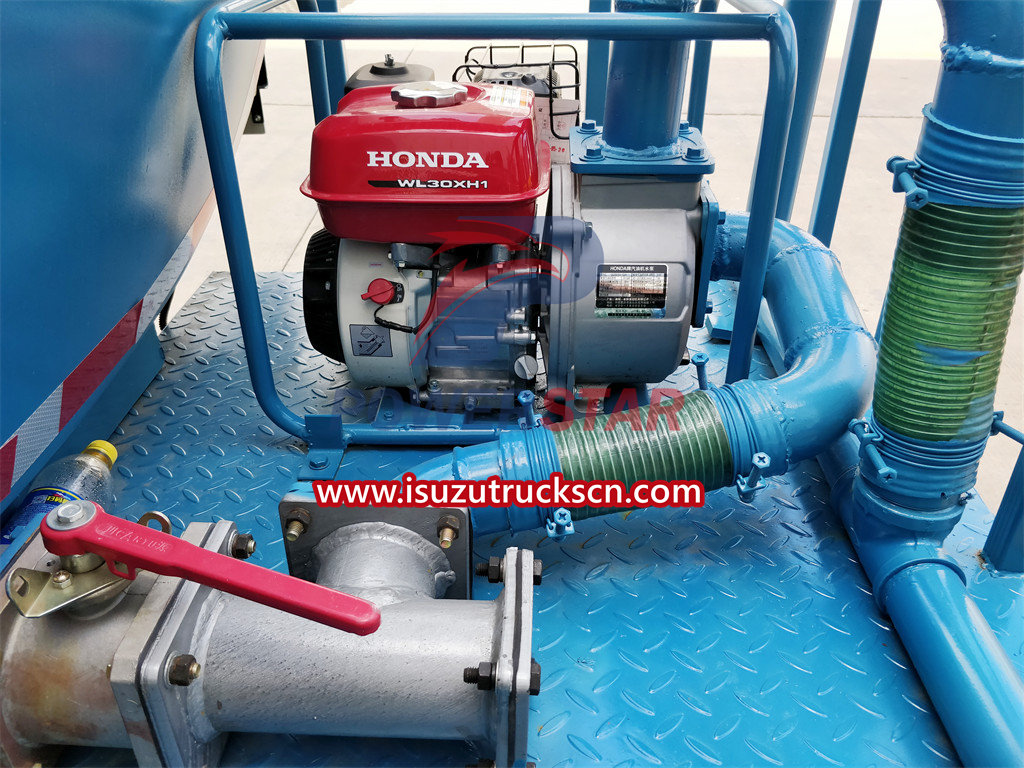

How to use the HONDA auxiliary engine:

• Understand the operation of all controls and learn how to stop the engine quickly in case of emergency. Make sure the operator receives adequate instruction before operating the equipment.

• Do not allow children to operate the engine. Keep children and pets away from the area of operation.

• Your engine’s exhaust contains poisonous carbon monoxide. Do not run the engine without adequate ventilation, and never run the engine indoors.

• The engine and exhaust become very hot during operation. Keep the engine at least 1 meter (3 feet) away from buildings and other equipment during operation. Keep flammable materials

away, and do not place anything on the engine while it is running.