POWERSTAR's Isuzu GIGA 16 cbm compression garbage truck is modified on the basis of Isuzu new FVR GIGA 5X cabin 4x2 chassis. It is equipped with an Isuzu 6HK1 240HP diesel engine, which has strong power and is matched with a FAST 9-speed gearbox. The gear shifting is smooth, and it is equipped with A/C, USB, and power steering. The vehicle is equipped with a 16-cubic-meter compression box and is equipped with 3 operating methods to maximize the compression efficiency.

Work capacity:

16cbmTruck model:

PT5180GXREngine power:

240HPEngine type:

Isuzu 6HK1-TCG61Axle drive:

4x2,left hand driveGear box:

FAST 9-speed,manualRemarks:

Isuzu New FVR 5X Cabin,with large capacity garbage boxIsuzu GIGA 16cbm refuse rear loaders are an efficient and energy-saving garbage disposal equipment. It has a large garbage bin volume of 16 cubic meters and adopts advanced compression technology to greatly compress the garbage volume to about 1/3 of the original volume, which greatly improves the efficiency of garbage disposal and reduces transportation costs.

This model is equipped with an Isuzu 6HK1 240 horsepower engine, which has strong power, high emission standards and meets environmental protection requirements. Its car body is automatically welded and formed with high-quality steel plates, with good sealing performance. The compression box body is built-in with a compression push plate to achieve two-way compression. The whole vehicle has beautiful shape and bright colors. It is both practical and beautiful, and is a powerful assistant for urban garbage disposal.

Key Features:

★ Various size body from 3cbm to 20cbm,

★ ISUZU engine,super powerful;reliable performance. no overhaul,within 1000000km

★lmported SlEMENS PLC integrated control high-efficient working

★Diffient rear lifting systerm are optional.

★Can be put into 20",40"container and ship to worldwide

|

Isuzu FVR GIGA 4X2 16CBM garbage compactor truck |

||||

|

Truck Specification |

||||

|

Model |

PT5180GXR |

|||

|

Cab |

ISUZU FVR GIGA 5X cabin,one and half row,with A/C,USB, drection assistance |

|||

|

Driving Type |

4x2,left hand drive |

|||

|

Max Speed (km/h) |

105 |

|||

|

Overall Dimension (mm) |

9070*2550* 3300 |

|||

|

GVW (kg) |

18000 |

|||

|

Curb weight(kg) |

9500 |

|||

|

Chassis |

||||

|

Wheelbase (mm) |

4500 |

|||

|

F/R Track Base (mm) |

2060/1855 |

|||

|

F/R Overhang (mm) |

1360/3210 |

|||

|

Tire |

295/80R22.5 |

|||

|

Clutch |

Single-plate dry diaphragm spring clutch |

|||

|

Steering |

Hydraulic steering with power assistance |

|||

|

Gear Box |

FAST 9-speed,manual |

|||

|

Bridge |

Front Axle (kg) |

6500 |

||

|

Rear Axle (kg) |

11500 |

|||

|

Engine |

||||

|

Engine |

Model |

Isuzu 6HK1-TCG61 |

||

|

Fuel Type |

Diesel fuel |

|||

|

Emission Standard |

Euro 6 |

|||

|

Type |

4 cylinder inline,water-cooled four-stroke, direct injection, turbocharged |

|||

|

Output Power (kw) |

240HP/177Kw |

|||

|

Exhaust(ml) |

7790 |

|||

|

Rotated speed(rpm) |

2400 |

|||

|

Max torque/max torque speed (N.m/rpm) |

760/1450 |

|||

|

Braking System |

Service Brake |

Compressed air brake |

||

|

Park Brake |

Spring energy |

|||

|

Auxiliary Brake |

Engine exhaust brake |

|||

|

Electrical System |

24v |

|||

|

Upper-Body Specification |

||||

|

Tank |

Volume |

16CBM |

||

|

Material |

Q345 |

|||

|

Thickness (side/bottom) |

4mm/5mm |

|||

|

Hydraulic Pump |

532 model |

1 set |

||

|

Multi-way Valve |

DL-15B-6 |

1 set |

||

|

Flap Cylinder |

80/45-410*180 |

2 set |

||

|

Lifting Cylinder |

80/45-900*580 |

2 set |

||

|

Scraper Cylinder |

80/45-700*415 |

2 set |

||

|

Skateboard Cylinder |

90/50-980*670 |

2 set |

||

|

Push plate Cylinder |

YSTB-1180*2420 |

1 set |

||

|

The Electromagnetic Valve |

UZCT-115/24V |

2 set |

||

|

Dirty Tank Volume |

200L |

|||

|

Filing Time |

8-15s |

|||

|

Filling Cycle Time |

50-60s each time |

|||

|

Discharge Type |

Flat-pushing and Dumping |

|||

|

Dumping Time |

30-40s |

|||

|

Hydraulic Pressure |

16Mpa |

|||

|

Controlling Way |

Manually and electrical control |

|||

Power performance

Equipped with Isuzu's new FVR GIGA 4X2 240HP diesel engine, it has strong power and high fuel economy. The engine has been carefully tuned to ensure that it can provide sufficient torque output at low speed to meet the power requirements of garbage trucks under various road conditions. At the same time, advanced emission control technology enables the vehicle to meet environmental protection requirements while reducing operating costs. Matching FAST 9-speed gearbox, smooth shifting.

Compression system

Adopts a high-performance compression mechanism with strong compression force and stable compression ratio. Through the advanced hydraulic control system, the automatic compression and loading of garbage are realized, which greatly improves the loading efficiency and processing capacity of the garbage truck. In addition, the compression system also has an automatic adjustment function, which can be intelligently adjusted according to different types of garbage to ensure the best compression effect.

Loading capacity

The compartment volume reaches 16 cubic meters, which can meet the collection needs of a large amount of garbage. At the same time, the interior of the compartment is made of high-strength wear-resistant materials, which has excellent corrosion resistance and durability, ensuring that it can still maintain good working condition under long-term use. In addition, the compartment also has an automatic opening and closing function to facilitate the loading and unloading of garbage.

Three operating methods

Here are three operating methods for Isuzu's new FVR GIGA 5X 4x2 16 cubic compression garbage truck.

1. Electric control box in the cab

In the cab, the electric control box is the core control device of the garbage compression truck. The driver can remotely start or stop the compression system by simply pressing the button on the control box. By adjusting the knob or button on the control box, the driver can also accurately control the operating speed and strength of the compression mechanism to ensure that the garbage is efficiently and tightly compressed while reducing energy consumption and noise.

Electric control box◁

Electric control box◁

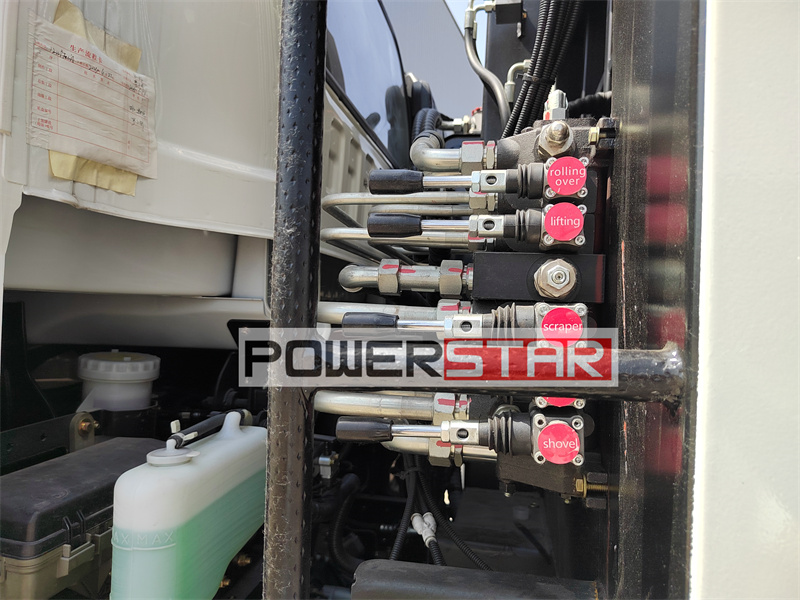

2. Drive side hydraulic operating joystick

The hydraulic operating joystick provides the driver with a more direct and flexible operating method. The hydraulic operating lever is located in the driving direction, which is convenient for the driver to operate outside the vehicle. By pulling or pushing the operating lever, the driver can manually control the hydraulic cylinder of the compression mechanism to start, stop and adjust the compression strength of the compression mechanism. In addition, the hydraulic operating lever is also equipped with loading and unloading control switches, through which the driver can manually control the opening and closing of the compartment to load and unload garbage. This operation method is particularly important when the electric control system fails or requires more direct operation, ensuring the reliability and flexibility of the garbage compactor.

▷ hydraulic operating joystick

3. Tailgate electric control operation box

The tailgate electric control operation box is located at the rear of the garbage truck compartment, which is convenient for ground staff or drivers to operate outside the vehicle. There are multiple control buttons and indicator lights on the operation box to control and monitor the operation.

Electric control box ◁

Electric control box ◁