The Isuzu 600P refueling truck is an efficient refueling vehicle aimed at the petroleum industry, aiming to bring users a more efficient and economical refueling experience. This fuel truck uses the most advanced technology and reliable components to ensure high-quality, high-performance fueling services for users. With its excellent fuel economy and high efficiency capabilities, the ISUZU fuel truck also has significant advantages in safety, comfort and sustainability.

Work capacity:

5000 LitersTruck model:

PT5050GJYEngine power:

130 HPEngine type:

4KH1CN5HSAxle drive:

4×2Gear box:

MSB 5-speed, manualRemarks:

European standard manhole cover, anti-corrosion inside the tank

ISUZU fuel truck is modified based on the Isuzu 600P chassis and is equipped with an Isuzu 4KH1 engine, which gives the vehicle continuous driving force. At the same time, with the optimization of the suspension system, it ensures that the vehicle can maintain stable driving in various road conditions, allowing you enjoy a comfortable driving experience. In order to ensure ride safety, the fuel tanker truck has specially strengthened the body structure to improve overall rigidity and anti-collision capabilities. A strong body improves vehicle safety by better retaining its integrity during a collision.

The ISUZU 5000L diesel bowser is fully equipped, which not only meets basic refueling needs, but also has many practical additional functions. Its large-capacity oil tank design means it can carry a large amount of oil to meet the needs of long-term operations. The pump has excellent performance and the oil pump has high working efficiency and can complete the refueling task quickly and accurately. The advanced refueling control system ensures the accuracy and safety of refueling and avoids the risk of oil leakage or incorrect refueling. The body is also equipped with multiple storage and tool boxes, which are designed to facilitate the driver to carry and use various tools and items, thereby improving work efficiency and convenience. This is a practical and safe fuel truck that gives you peace of mind whether it's a large job or daily use.

Product Specifications

|

Vehicle Information |

|

|

Product Model |

PT5050GJY |

|

Driving Type |

4×2, Left hand drive |

|

Max. speed |

90 km/h |

|

Weights |

|

|

Gross vehicle weight (kg) |

7300 |

|

Curb weight(kg) |

3500 |

|

Dimensions |

|

|

Wheelbase(mm) |

3360 |

|

Overall dimension (mm) |

5990×2000×2400 |

|

Front wheel track (mm) |

1504 |

|

Rear wheel track (mm) |

1425 |

|

Engine |

|

|

Engine model |

4KH1CN5HS |

|

Engine power |

96KW/130HP |

|

Emission standard |

Euro 5 |

|

Engine type |

4 stroke water-cooled, in-line, inter-cooling, turbocharged |

|

No. of cylinders |

4 cylinders |

|

Displacement |

2999 L |

|

Rated speed |

3400 rpm |

|

Max. torque |

290 N.m |

|

Transmission |

|

|

Gear box |

MSB, 5 forwards,1 reverse gear, manual |

|

Steering |

With power steering |

|

Axle |

|

|

Front axle |

2.5 tons |

|

Rear axle |

4.8tons |

|

Tire specification |

|

|

Tire specification |

7.00R16 standard tire,6 tires+1 spare tire |

|

Specification of fuel tanker |

|

|

Tanker volume |

5000 liters |

|

Tanker shape |

Ellipse water tanker |

|

Tanker material |

Q235,carbon steel,4mm |

|

Manhole |

DN500mm manhole with European standard cover |

|

Horse reels |

Two 75 ft hose reels at each side of the truck |

|

Standard configuration |

With pump |

|

optional |

compartments, bottom loading, flow meter, oil vapor recovery, |

|

fuel dispenser |

|

|

float level gauge |

|

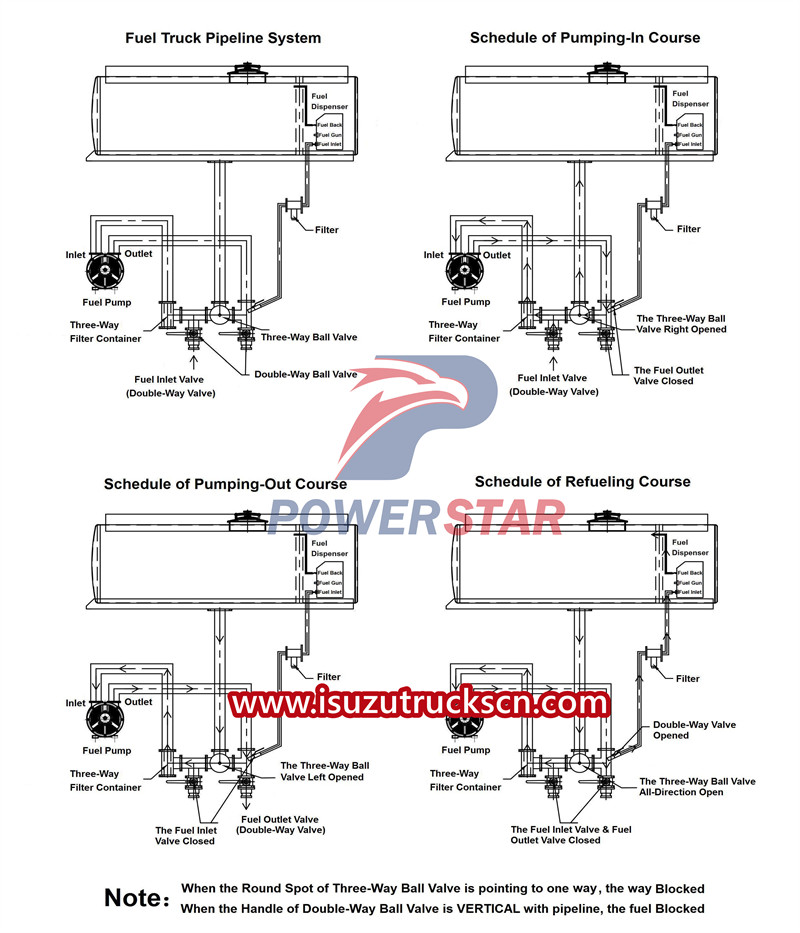

Fuel truck pipeline structure

As a special vehicle, the pipeline structure of a fuel truck is crucial to ensuring the safe and efficient transmission of fuel. The following are the main components of the fuel truck pipeline structure:

1. Oil tank and valve:

• Oil tank: As the main container for storing oil, it must have sufficient strength and sealing properties. Usually made of high-strength steel and treated with anti-corrosion treatment both internally and externally.

• Valve: Valves are used to control the inflow and outflow of oil. Common ones include ball valves, gate valves, etc. The valve needs to have excellent sealing performance to ensure that oil does not leak.

2. Filling pipe:

• Main pipeline: The pipeline connecting the oil tank and the dispenser must have sufficient strength and pressure resistance.

• Branch line: The pipe that connects the fuel dispenser to the vehicle's fuel tank. It is usually equipped with a quick connector to facilitate connection to the vehicle's fuel tank.

3. Quick release device:

• In order to improve refueling efficiency, the pipeline is usually equipped with a quick release device. This device can be quickly disassembled and assembled, reducing manual operation time.

4. Oil filter:

• In order to ensure the quality and cleanliness of the oil, filters are usually installed in the pipelines. Filters remove impurities and moisture from oil.

5. Oil and gas recovery device:

• During the refueling process, some oil vapor will evaporate. The oil and gas recovery device can recover this part of oil and gas to reduce environmental pollution.

6. Emergency shut-off valve:

• When an abnormal situation occurs, the valve can be quickly closed to cut off the flow of oil to prevent the accident from expanding.

7. Anti-overflow valve:

• When the oil dispenser or pipeline fails and causes oil to backflow, the anti-overflow valve can automatically close to prevent oil from overflowing.

8. Pressure gauge and thermometer:

• Used to monitor the pressure in the pipeline and the temperature of the oil to ensure the safety and stability of the refueling process.