Isuzu portable fuel bowser is a special vehicle equipped with oil tank, oil pump, pipelines, refueling device, ancillary accessories and safety protection devices. This ISUZU tank truck is generally used to load flammable and explosive chemical dangerous goods, such as gasoline, diesel or kerosene and other light fuels.

Work capacity:

5000 LitersTruck model:

PT5050GJYEngine power:

120 HPEngine type:

4KH1CN6LBAxle drive:

4×2Gear box:

MSB 5-speed, manualRemarks:

Fuel tanker with dispenser, customized logo and painting

ISUZU refueling truck, also known as ISUZU mobile fuel bowser, is a special vehicle that can provide refueling services at different locations. They are usually equipped with main components such as refueling machines, automatic reels, refueling guns, and pumps on the basis of truck chassis to realize the transportation and refueling of oil.

ISUZU mobile fuel trucks are mainly used for the transportation and storage of petroleum derivatives (such as gasoline, diesel, crude oil, lubricants, coal tar and other oil products). According to different uses and usage environments, mobile fuel trucks have a variety of refueling or oil transportation functions, including oil suction, oil pumping, oil distribution, and refueling.

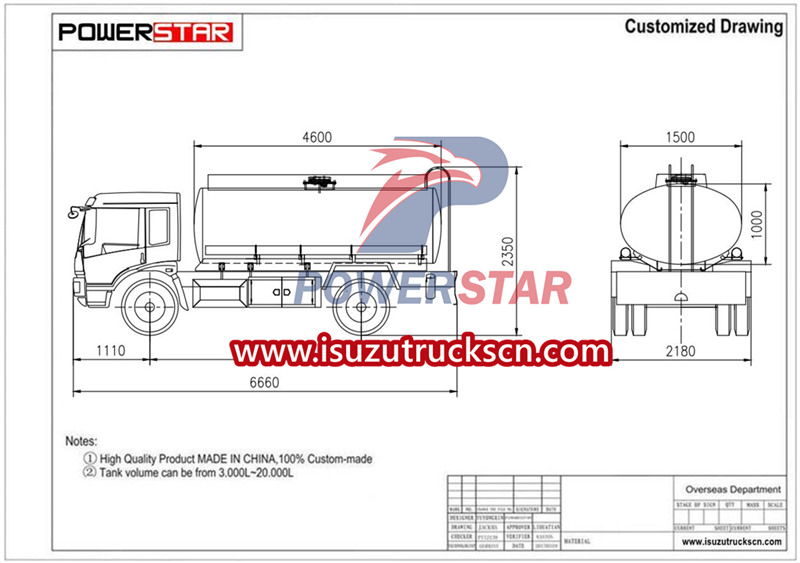

Product Specifications

|

Vehicle Description |

||

|

Overall dimensions |

5900*2200*2500mm |

|

|

GVW |

7300kg |

|

|

Curb weight |

4200 kg |

|

|

Chassis brand |

ISUZU |

|

|

Driving type |

4*2 |

|

|

Tanker Description |

||

|

Tank capacity |

5000 liters |

|

|

Tanker material |

Carbon steel |

|

|

Thickness |

Tanker body |

4mm |

|

End cover |

4mm |

|

|

Tanker shape |

Ellipse |

|

|

Tanker compartment |

1 compartment (optional: several compartments) |

|

|

Standard configuration |

1 set European standard manhole cover |

|

|

Equipped with double discharge valve and valve box. |

||

|

Equipped with surge baffles, ladder, roof coaming, skid resistant walkway, and toolbox. |

||

|

Electrostatic conducting tape and double fire extinguishers. |

||

|

Optional |

Tanker material: aluminum alloy; stainless steel |

|

|

Chinese standard configuration is available, or other world famous fuel configuration. |

||

|

Over flow probe system, vapor recovery system, bottom valve, API adaptors. |

||

|

Emergency bottom valve and foldable aluminum handrail. |

||

|

Others: fuel pump, refueling dispenser, flow meter, dipstick, etc. |

||

|

Chassis Description |

||

|

Cab |

3 Passenger , with air-conditioner. |

|

|

Wheelbase |

3360 mm |

|

|

Tire specification |

7.00R16 |

|

|

Tire quantity |

6+1 units |

|

|

Engine |

Brand |

ISUZU |

|

Model |

4KH1CN6LB |

|

|

Emission standard |

Euro 6 |

|

|

Power |

120 HP |

|

|

Displacement |

2999 ml |

|

|

Gear box |

Type |

Manual |

|

Number of gears |

5 forward gears& 1 reverse |

|

|

Brake system |

Air brake |

|

|

Axle |

Front |

2500kg |

|

Rear |

4800 kg |

|

|

Suspension |

Leaf springs |

|

|

Fuel tanker |

Type |

Steel tanker, with lockable cap |

Application scenarios of ISUZU fuel tanker trucks:

1. Urban services: Applicable to all types of vehicles in the city, such as buses, taxis, cars, etc.

2. Logistics and transportation: Provide timely refueling services for vans, trucks and other logistics vehicles.

3. Construction site: Provide energy supply for heavy equipment on the construction site.

4. Rural areas: Provide energy support for agricultural machinery and other equipment.

5. Emergency rescue: Provide rapid energy supply for rescue vehicles in disasters or emergencies.

Safety precautions during operation of Isuzu fuel tank bowser

1. Follow the operating procedures

1) Strictly abide by the operating procedures of the fuel truck to ensure that every step of the operation complies with safety standards.

2) Conduct regular safety training to ensure that operators are familiar with and master all safety procedures.

3) Do not attempt illegal operations at any time, and seek professional help even in emergencies.

2. Check the condition of the equipment

1) Before each use, the equipment of the ISUZU fuel truck should be fully inspected to ensure that there is no damage or leakage.

2) Perform regular equipment maintenance and upkeep to ensure it is in optimal working condition.

3) If any equipment problems or malfunctions are found, stop using them immediately and have them repaired.

3. Pay attention to environmental safety

1) The ISUZU oil tank truck should be parked in a flat and open place, away from flammable materials and fire sources.

2) Ensure the work area is well ventilated to avoid possible accumulation of oil and vapor.

3) In windy conditions, pay special attention to the spread of oil and gas and the control of fire sources.

4. Control oil volume and speed

1) During the refueling process, the amount of oil must be strictly controlled to avoid overfilling the tank and overflowing.

2) The oil flow speed should not be too fast when refueling to prevent fire caused by static electricity.

3) Regularly check the working status of the oil pump and oil pipes to prevent safety accidents caused by leaks.

5. Wear protective equipment

1) All operators must wear personal protective equipment such as protective clothing, protective gloves and protective shoes.

2) During the refueling process, a gas mask should be worn to prevent oil gas poisoning.

3) Wear a static eliminator when working in areas where static electricity may be generated.

6. No smoking and no listening to mobile phones

1) Smoking or using open flames near fuel trucks is strictly prohibited.

2) It is prohibited to answer or use mobile phones during the refueling process to prevent fire caused by static electricity.