Isuzu mobile fuel tanker, also known as ISUZU refueler truck, can be equipped with oil pumps to pump oil in and out, and equipped with oil dispensers, which can fill different types of oil products to other equipment anywhere. The vehicle is built on the basis of an Isuzu all-wheel drive chassis. The tank is made of carbon steel and is divided into two independent compartments for transporting different types of oil products.

Work capacity:

6000 LitersTruck model:

PT5060GJYEngine power:

190 HPEngine type:

4HK1-TC51Axle drive:

4×4Gear box:

MLD 6-speed manualRemarks:

ISUZU off-road chassis, tanker with two compartments

ISUZU fuel bowser, also known as ISUZU fuel tanker truck, is a special vehicle used for transportation and refueling fuel. They are often equipped with tanks and refueling equipment to fuel cars, trucks and other vehicles at various locations. Fuel tanker trucks play an important role in daily life, ensuring the normal operation of vehicles and smooth traffic.

The tank material of Isuzu mobile fuel trucks is usually made of high-quality steel plates, which have certain corrosion resistance. In order to further improve the corrosion resistance of the tank, the outer surface of the tank is usually sprayed with anti-corrosion, anti-rust, and anti-oxidation treatments. In addition, the inside of the tank will also be treated with anti-rust treatment to prevent oil from corroding the inside of the tank.

Isuzu fuel bowser trucks are mainly used to load and transport oil products, including diesel, gasoline, lubricants, etc. These oils can be transported to other equipment or vehicles through the oil pumps and pipelines inside the fuel truck to meet various needs. When using an Isuzu fuel truck, you need to follow relevant safety regulations and operating procedures to ensure the safety and reliability of loading and transporting oil products.

Product Specifications

|

Truck Specifications |

||

|

Truck model |

PT5060GJY |

|

|

Cab |

ISUZU NPR/NQR cab |

|

|

Driving Type |

4*2 Left hand driving |

|

|

Max Speed (km/h) |

90 |

|

|

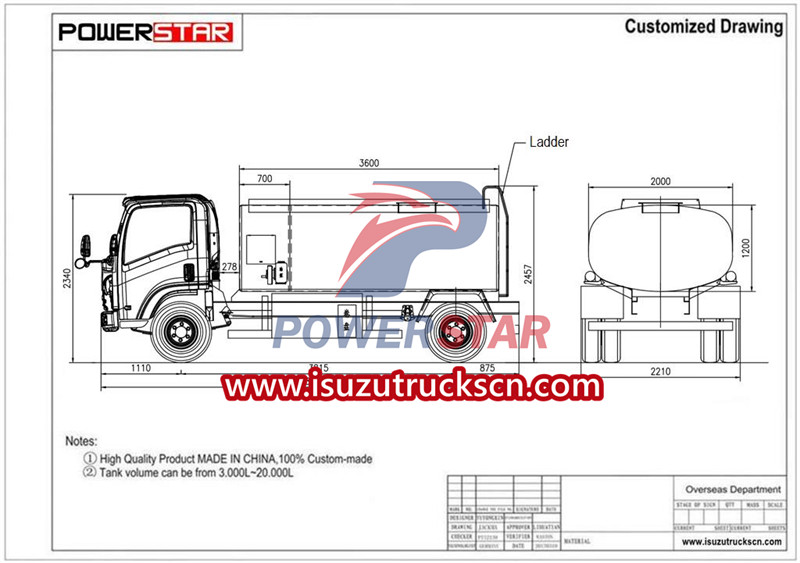

Overall dimension(mm) |

6800*2200*2600 |

|

|

GVW(kg) |

11000 |

|

|

Curb weight(kg) |

5400 |

|

|

Fuel Tank Capacity (L) |

6000 |

|

|

Wheelbase(mm) |

3815 |

|

|

F/R track base(mm) |

1960/1855 |

|

|

F/R overhang(mm) |

1110/2000 |

|

|

Approach/Departure Angel |

16/10 |

|

|

Tire |

235/75R17.5 |

|

|

Clutch |

Single-plate dry diaphragm spring clutch |

|

|

Steering |

Hydraulic steering with power assistance |

|

|

Gear box |

MLD 6-speed, manual |

|

|

Axles |

Front axle |

4T |

|

Rear axle |

7T |

|

|

Engine |

Model |

4HK1-TC51 |

|

Fuel Type |

Diesel fuel |

|

|

Type |

Water-cooled four-stroke,, direct injection, turbocharged |

|

|

Displacement(ml) |

5193 |

|

|

Max output power (hp) |

190 |

|

|

Max Torque (N.m) |

510 |

|

|

Rated speed |

2600 rpm |

|

|

Braking system |

Service Brake |

Compressed air brake |

|

Park Brake |

Spring energy |

|

|

Auxiliary brake |

engine exhaust brake |

|

|

Eletric system |

24v |

|

|

Upper-body specification |

||

|

Volume of tank |

6000 liters |

|

|

Tank shape |

elliptical |

|

|

Material of tanker |

4mm carbon steel |

|

|

Color of the tanker |

As required |

|

|

Transport medium |

Diesel, fuel, oil, petrol or others |

|

|

Fittings |

PTO, gear pump |

|

|

An aluminum alloy European standard manhole cover |

||

|

Fuel hose box fitted on both side of tank |

||

|

An aluminum alloy bottom valves |

||

|

Two Fire extinguisher |

||

|

One spare tyre |

||

|

Ladder: For access to top of tank complete with cat walk on top of tank |

||

|

Heavy-duty rear bumper |

||

The tank structure features of Isuzu mobile fuel trucks mainly include the following:

1. Tank shape: The tank of the Isuzu mobile fuel truck adopts an elliptical cylindrical design. This shape can better adapt to the movement of the vehicle and the vibration generated during driving, and improve the rigidity and strength of the tank.

2. High-quality materials: The tank is made of high-quality steel plate, which has high corrosion resistance and impact resistance, ensuring the service life and safety of the tank.

3. Separate compartment design: The interior of the tank adopts a compartment design. Each compartment can be refueled or stored independently, which can better control the quality and quantity of oil products and reduce the possibility of oil mixing.

4. Internal reinforcement: Structures such as reinforcing ribs and beams are used inside the tank to improve the rigidity and strength of the tank and ensure the stability and safety of the tank.

5. Safety devices: Safety devices such as safety valves and breathing valves are installed on the top of the tank to ensure the safe storage and transportation of oil products. In addition, the tank is also equipped with anti-overflow devices and anti-static devices to further ensure safe use.

6. Appearance design: The outer surface of the tank is spray-coated with anti-corrosion, anti-rust and anti-oxidation to ensure beautiful appearance and durability.