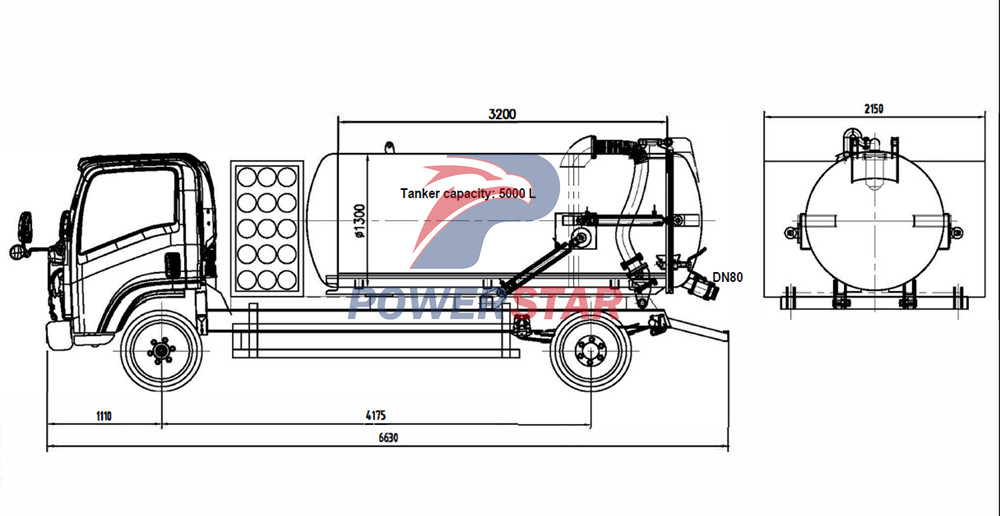

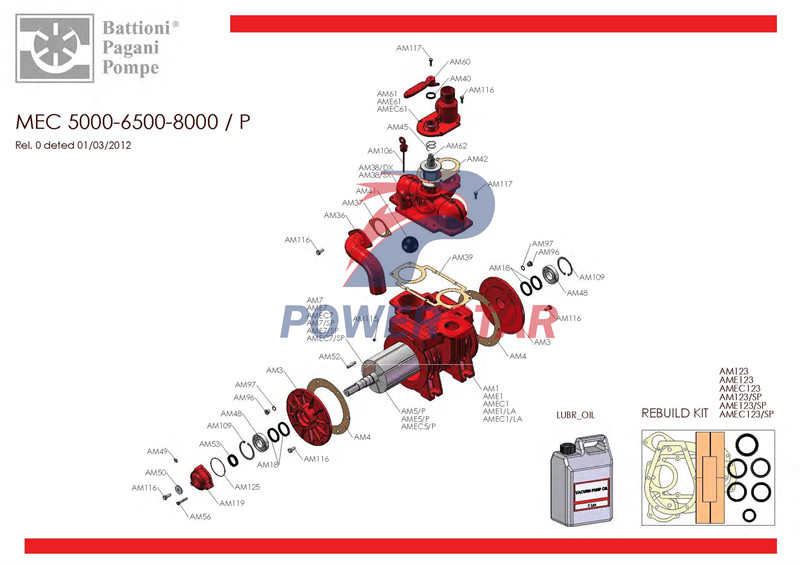

Isuzu septic tank pump truck is equipped with high-performance diesel engines with low noise and low fuel consumption, and are matched with mature and stable gearboxes. The truck is equipped with an Italian BP MEC6500 vacuum pump, which has large suction power and high efficiency. The vehicle's hydraulic system has fast response speed, high control accuracy and stable operation. The vacuum tank is made of high-quality materials, with high strength, corrosion resistance, long life, and a smooth interior for easy cleaning and maintenance. In addition, it is also equipped with a liquid level gauge and a pressure gauge to facilitate the operator to grasp the working status of the tank.

Work capacity:

5000 LitersTruck model:

PT5050GXWEngine power:

4HK1-TC51Engine type:

190 HPAxle drive:

4×2Gear box:

MLD 6-speed manualRemarks:

Italy BP MEC6500 vacuum pump, customized DN80 suction hoseISUZU sewer pump truck, also known as ISUZU sewer vacuum truck, ISUZU sewage tank truck, or ISUZU sludge removal truck, is a special vehicle used to collect, transport, disposal and clean sewage, sludge and other waste. It is widely used in urban environmental sanitation, sewage treatment and other fields.

The collection system of ISUZU sewer pump truck usually consists of a sewage suction pipe, a vacuum pump and a tank. During operation, the sewage suction pipe goes deep into waste sources such as sewage pools, toilets, and sewers, and uses powerful vacuum suction to suck the waste into the tank. An anti-sedimentation device is designed inside the tank to prevent waste from settling and clogging. During the transfer process, the sewage suction truck will transport the waste to the designated disposal location.

The inside of the tank of ISUZU sewage truck is usually made of anti-corrosion and anti-rust materials to ensure the service life of the tank. There is also a stirring device inside the tank to prevent waste from settling in the tank. During the treatment process, the sewage suction truck can transport the waste to a sewage treatment plant or designated treatment equipment for further treatment and purification.

After the treatment is completed, the septic tank truck can perform discharge operations. Before discharge, ensure that the waste in the tank has been completely processed and purified to avoid secondary pollution to the environment. During the cleaning process, the sewage tank truck can use high-pressure water guns to clean the inside of the tank to ensure the cleanliness and hygiene of the tank.

Product Specifications:

|

Vehicle Description |

||

|

Overall dimensions |

6700*2200*2500mm |

|

|

GVW |

11000kg |

|

|

Curb weight |

5800kg |

|

|

Chassis brand |

ISUZU |

|

|

Driving type |

4*2, LHD |

|

|

Chassis Description |

||

|

Steering |

Power assist |

|

|

Cab |

ELF, single row, with A/C, ABS, 3 seats |

|

|

Wheelbase |

3815mm |

|

|

Tire specification |

235/70R17.5 |

|

|

Tire quantity |

6 tires and 1 spare tire |

|

|

Engine |

Engine model |

4HK1-TC51 |

|

Emission standard |

EURO 5 |

|

|

Power |

190HP/140KW |

|

|

Displacement |

5193cc |

|

|

Torque |

5100N.m |

|

|

Gear box |

Model |

ISUZU MLD |

|

Type |

Manual |

|

|

Number of gears |

6-speed |

|

|

Brake system |

Air break |

|

|

Axle |

Front |

4000 kg |

|

Rear |

1000 kg |

|

|

Fuel tanker |

Type |

Iron |

|

Capacity |

100L |

|

|

Tanker Description |

||

|

Tanker |

Capacity |

5000 Liters |

|

Material |

6mm thickness, high quality carbon steel |

|

|

Structure |

Welding, vacuum tank, cylindrical |

|

|

Pump |

Type |

Vacuum pump |

|

Make |

Battioni Pagani (BP) |

|

|

Model |

MEC6500 |

|

|

Flow |

7000 (L/min) |

|

|

Speed |

1400 (r/min) |

|

|

Max. vacuum |

-094 bar |

|

|

Pipe |

Suction and discharge pipe |

|

|

Special function |

Suction time ≤ 5min, |

|

|

Standard configuration |

Equipped with sight tube, discharge valve, liquid level alarm, 7 meter suction hose, oil-water separators, overflow valve, etc. |

|

|

Optional configuration |

Tanker material: stainless steel. Water jetting device |

|

How to extend the service life of ISUZU sewage truck?

In order to ensure the normal operation of ISUZU sewage tank truck and extend its service life, a series of measures need to be taken.

1. Regular maintenance

A vacuum tanker truck is a heavy-duty vehicle that requires regular maintenance and repairs. According to the manufacturer's recommendations, regularly replace wearing parts such as engine oil, air filter, fuel filter, etc. to ensure the normal operation of the engine and other mechanical components. At the same time, check and adjust key components such as the braking system, steering system, and suspension system to ensure the safety and stability of the vehicle.

2. Reasonable use

1. Avoid overloading: The load-carrying capacity of ISUZU sewage suction trucks is limited. Overloading will not only affect the performance of the vehicle, but also cause excessive pressure on the vehicle's components and accelerate their damage.

2. Maintain an appropriate speed: Use the septic tank lorry at an appropriate speed and avoid too fast or too slow speeds, which can reduce vehicle wear and damage.

3. Avoid sudden acceleration and braking: Frequent sudden acceleration and braking will cause the vehicle components to bear excessive pressure, which will have a negative impact on the life of the vehicle.

3. Keep it clean

Keeping the exterior and interior of your truck clean will prevent dirt and corrosion from damaging the vehicle. Regularly clean the exterior and interior of the vehicle, including the body, chassis, tires, cabin and other parts. At the same time, pay attention to cleaning key components such as the engine and hydraulic system to prevent clogging and corrosion.

4. Preventive maintenance

Preventive maintenance refers to repairs and inspections before failures occur to prevent potential problems and failures. Regular preventive maintenance of sewage trucks can detect and deal with potential problems in time and extend the service life of the vehicle. Preventive maintenance includes checking key indicators such as oil level, water level, and tire pressure, as well as replacing wearing parts.

5. Timely maintenance

Once a malfunction or abnormal situation is found in the vacuum suction truck, it should be repaired and processed in time. Prevent small problems from turning into big problems and affecting the normal operation and service life of the vehicle. At the same time, keep in touch with professional maintenance personnel so that you can get timely help and guidance when needed.

6. Driver training

The driver's skills and experience have a great impact on the life and effectiveness of the sewage suction truck. Therefore, drivers should be trained and educated regularly to improve their driving skills and understanding of vehicles. The training content includes safe driving, maintenance, emergency handling, etc.

7. Recording and Tracking

Establish a detailed recording and tracking system to record and track the maintenance and use of sewer trucks. This helps to detect and deal with problems promptly and avoid potential failures and damage. The recorded content can include vehicle usage, maintenance records, driver operating habits, etc. By tracking this information, you can better understand the condition and usage of the vehicle, providing a basis for extending its service life.

8. Choose the right accessories

Choosing the right accessories is crucial to extending the service life of your sewage truck. Use original or certified compatible accessories to ensure your vehicle's performance and safety. Avoid using inferior or unsuitable accessories, which may cause failure or reduce the life of the vehicle.