Oil tanker trucks are mainly used for the transportation of petroleum, refined oil, chemical liquids and other media. In daily life, tank trucks are mainly responsible for the transportation tasks between oil depots and gas stations, ensuring that all types of oil products can be delivered to their destinations in a timely and safe manner. In addition to daily transportation, oil tanker trucks are often used to supply oil products in emergencies such as rescue and disaster relief. They are an indispensable and important part of the modern transportation and logistics system.

Work capacity:

5000 LitersTruck model:

PT5050GJYEngine power:

130 HPEngine type:

4KH1CN5HSAxle drive:

4×2Gear box:

MSB 5-speed, manualRemarks:

ISUZU NKR light duty chassis, China famous brand fuel dispenser

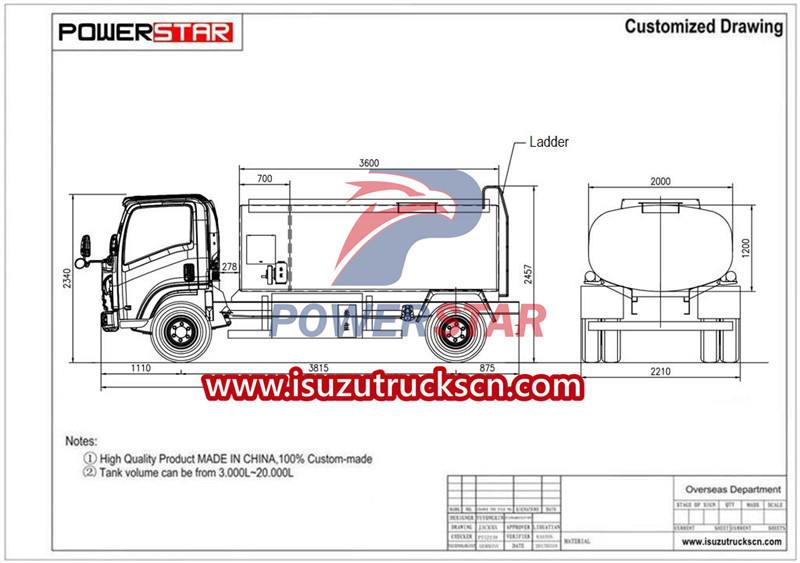

The Isuzu NKR mobile diesel bowser is a very efficient, safe and reliable oil transport vehicle. It is highly praised for its excellent performance and stable transportation capacity. This vehicle is a high-performance fuel truck designed based on the Isuzu 600P (NKR) light duty chassis and combined with actual transportation needs. Not only can it meet the needs of various complex transportation environments, but it also has many unique features and advantages.

One of the features of the Isuzu NKR mobile diesel bowser is its efficiency. The vehicle uses an advanced engine and transmission system to provide excellent power and fuel economy in a variety of road and transportation conditions. This allows the Isuzu NKR fuel bowser to complete a large number of transportation tasks in a short time and save energy costs.

Safety is another important feature of the Isuzu NKR mobile diesel bowser. The vehicle adopts multiple safety systems, including explosion-proof devices, emergency braking systems and hazardous gas detection systems, to ensure safety during transportation. In addition, the truck also has good shock-proof performance and stability, which can maintain stable driving in complex road conditions and avoid accidents.

Product Specifications

|

Vehicle Technical Parameters |

|

|

Curb Weight(Kg) |

7300 |

|

Boundary Dimension(mm) |

5900×2200×2400 |

|

Tank Volume(L) |

5000L |

|

Tank Thickness(mm) |

4 |

|

Tank Body Material |

Q235 Carbon Steel |

|

Anti-wave plate |

Factory standard |

|

Operating Ambient Temperature(°C) |

-20~45 |

|

Manhole cover |

European standard |

|

Emergency shutoff valve |

Factory standard |

|

Oil gas recovery unit |

Factory standard |

|

Anti-overflow alarm device |

Factory standard |

|

Fuel loading method |

Bottom filling |

|

Oil pump flow(m³/h) |

30 |

|

Fuel dispenser |

China famous brand |

|

Toolbox |

Factory standard |

|

Maximum Speed(km/h) |

80 |

|

Chassis Technical Parameters |

|

|

Chassis brand |

ISUZU |

|

Chassis type |

Light duty |

|

Driving type |

4×2, LHD |

|

Type of fuel |

Diesel |

|

Engine model |

4KH1CN5HS |

|

Engine power(KW/HP) |

96KW/130HP |

|

Displacement (ml) |

2999 |

|

Emission standard |

Euro 5 |

|

Front wheel braking |

Disc brake |

|

Front Axle/Rear Axle(kg) |

2500/4800 |

|

Gearbox |

5 Speed Manual Transmission |

|

Brake |

Oil brake |

|

Number of Axles |

2 |

|

Wheelbase (mm) |

3360 |

|

Number of Tires |

6+1 |

|

Tyre Specification |

7.00R16 |

Advantages of Isuzu fuel bowser truck:

1. The tank is formed in one step, safe and pressure-resistant.

The tank body adopts one-piece molding technology, which has strong pressure and explosion-proof capabilities. It adopts automatic seamless welding technology, which has good sealing performance and beautiful welding points.

2. The head adopts hydraulic technology, which has stronger pressure-bearing and sealing capabilities.

The head adopts the processing method of CNC cutting and hemming after the flat plate is formed by water pressure, which has greater pressure bearing capacity and stronger sealing effect.

3. The head is welded using automatic welding technology, making it more beautiful.

The tank head is automatically welded by a welding robot, with better welding effect and more beautiful welds.

4. Oil and gas recovery device

The oil and gas recovery device can avoid the leakage of oil and gas, and the oil and gas can be condensed and reused through other oil and gas recovery devices, thereby achieving the purpose of environmental protection.

5. European standard can mouth

The aluminum alloy European standard manhole cover integrates a built-in breather, oil and gas recovery valve, oil measuring hole, and anti-overflow probe rod.

The main structure of ISUZU potable fuel bowser:

1. Oil tank: The oil tank is the core component of ISUZU oil tanker truck and is used to store various oil products. Oil tanks are generally made of welded steel plates and have good anti-corrosion and sealing properties. Depending on the type and characteristics of the oil, the inside of the oil tank is usually treated with anti-rust treatment and equipped with corresponding heating and insulation facilities.

2. Pump: ISUZU fuel tanker truck is equipped with oil pump to pump oil out of the tank and deliver it to the destination. The types and specifications of oil pump depend on the specific use. Common ones are self-priming centrifugal pumps and vane pumps.

3. Valves: Valves are key components that control the inflow and outflow of oil, mainly including ball valves, stop valves, etc. The valve needs to have good sealing performance and switch flexibility to ensure the safety of oil products during transportation.

4. Safety devices: In order to ensure safety during transportation, ISUZU fuel tanker truck is equipped with a series of safety devices. These devices include overflow valves, emergency shut-off valves, pressure gauges, thermometers, and liquid level gauges.

5. Pipelines: Pipelines are used to connect oil tanks, pump, valves and other components to form a complete oil delivery system. Pipes are usually made of corrosion-resistant high-quality materials, such as stainless steel or copper alloys.