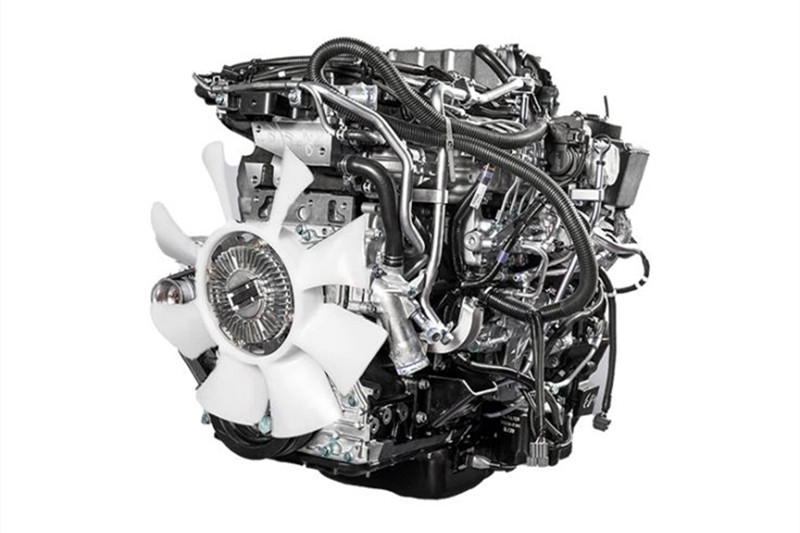

Brand new ISUZU N series truck chassis, to be mounted with 4KH1CN diesel engine, with engine power can be 98HP or 120HP, 4 Cylinders in line, turbo charging, inter cooling, high pressure common-rail diesel injection system, liquid-cooled engine. 4x2 or 4x4 truck drive model with front axle 2.5tons and rear axle 4.8tons. In cabin comfortable driving feeling with Air conditional equipped, also AM/FM radio and USD MP3 for video play. The truck can be mounted with ISUZU garbage compactor truck, Isuzu road sweeper truck, Isuzu sewage truck, Isuzu fire truck, Isuzu tanker trucks, etc.

Work capacity:

2-5 tonsTruck model:

PT5070BUHACYEngine power:

98 hpEngine type:

4KH1CNAxle drive:

4x2Gear box:

MSB 5-shift ManualRemarks:

Original Japanese technology ISUZU NKR truck chassis

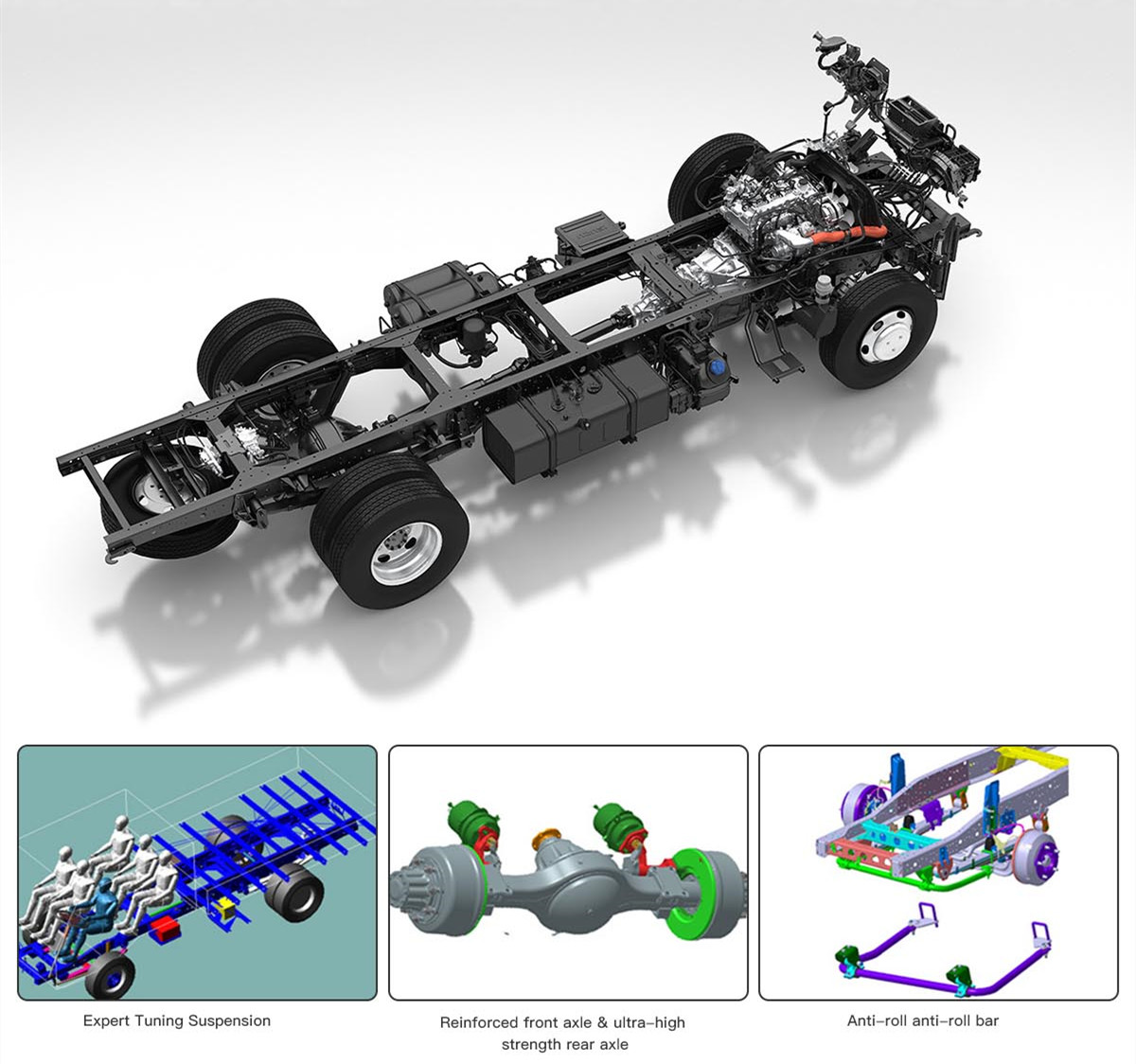

ISUZU truck chassis is a truck chassis with a strong and durable structural design that provides a good foundation for the truck. The following is the common structure of ISUZU truck chassis:

1. Cab: The cab of ISUZU truck chassis usually adopts an all-steel structure, which is strong and durable. The cab is designed with impact resistance and driver safety in mind. The cab has ample space to provide the driver with a comfortable experience when driving for long periods of time. The interior layout is reasonable and provides ample headroom and legroom to meet the driver's comfort needs.

2. Main beam: The main frame of the ISUZU truck chassis is composed of strong main beams. The main beam is a long beam that runs from front to rear and is responsible for carrying the overall weight and torque of the vehicle. It is typically made from high-strength steel to ensure structural stability and durability throughout the vehicle.

3. Front suspension: ISUZU truck chassis has an independent front suspension system, which usually uses springs and shock absorbers to provide a comfortable suspension effect while buffering road bumps and impacts. This design also provides better handling stability and ride smoothness.

4. Rear suspension: The rear suspension system of ISUZU truck chassis usually uses leaf springs and shock absorbers to support and alleviate the rear load of the vehicle. The rear suspension structure is reasonably designed to withstand rear loads and maintain vehicle stability.

5. Drive system: ISUZU truck chassis usually uses a rear-wheel drive or all-wheel drive system to provide powerful power output and excellent passing capabilities. The drive system includes the engine, transmission and drive shaft, ensuring that the vehicle can operate efficiently under various road conditions.

6.Braking system: ISUZU truck chassis is equipped with a reliable braking system to ensure safe parking and deceleration of the vehicle. Usually includes air braking system, hydraulic braking system or a combination thereof to meet the needs of different models.

7. Front and rear axles: The front and rear axles of the ISUZU truck chassis are responsible for transmitting power from the engine to the wheels, and at the same time bear the load and torque of the vehicle. These bridges are usually made of reinforced alloy steel to ensure their load-bearing capacity and durability.

The structural design of the ISUZU truck chassis takes into account the vehicle's load-bearing, suspension and power transmission to meet the needs of different working conditions. The design and quality of these structures ensure the reliability and durability of the ISUZU truck chassis, providing a reliable foundation for a variety of applications.

Products Parameters for ISUZU 4x2 / 4x4 light duty diesel engine truck chassis:

|

Model No. |

||||||

|

|

|

QL1040A6EAY |

QL1040A6FAY |

QL1047A6HAY |

QL1070A6KAY |

|

|

Wheelbase |

||||||

|

Wheelbase |

(mm) |

2490 |

2765 |

3360 |

3815 |

|

|

Drive Type |

||||||

|

|

4 × 2 |

|||||

|

Weight & Capacities |

||||||

|

GVW |

(kg) |

4000 |

4495 |

7300 |

7300 |

|

|

Curb Weight |

(kg) |

1750 |

1950 |

2100 |

2110 |

|

|

Pay Load |

(kg) |

2000 ~ 4500 |

||||

|

Cabin |

||||||

|

Type |

|

Single |

||||

|

Driver & Passenger |

|

1+1 |

||||

|

Engine |

||||||

|

Model |

|

4KH1CN5LS |

||||

|

Type |

|

4 cylinders in

line, |

||||

|

Emission Standard |

|

EURO 5/6 |

||||

|

Displacement |

(L) |

2..999 |

||||

|

Rated Power |

(kw/rpm) |

72(98hp)/3400 |

||||

|

Max. Torque |

(N.m/rpm) |

220/1700 |

||||

|

Transmission |

||||||

|

Model |

|

manual, ISUZU MSB-5S (5 forward+1 reverse) |

manual, ISUZU MSB-5MT, (5 forward+1 reverse) |

|||

|

Gear Ratio |

|

5.016/2.524/1.489/1.000/0.713/R:4.783 |

5.594/2.814/1.660/1.000/0.794/R:5.334 |

|||

|

Clutch |

||||||

|

Type |

|

dry, single plate with cushioning spring |

||||

|

Axle Load |

||||||

|

Front (type) |

|

reverse Elliot "I" beam |

||||

|

Front |

(T) |

2.2 |

2.5 |

2.5 |

2.5 |

|

|

Rear (type) |

|

Banjo, full floating type |

||||

|

Rear |

(T) |

3 |

4.8 |

4.8 |

4.8 |

|

|

Frame |

||||||

|

Type |

|

ladder type |

||||

|

Width |

(mm) |

800 |

700 |

700 |

700 |

|

|

Suspensions |

||||||

|

Front (type) |

|

semi-elliptical, leaf spring, double acting telescopic shock absorber |

||||

|

Front (quantity) |

|

6 |

8 |

|||

|

Rear (type) |

|

semi-elliptical, Alloy steel leaf spring, double acting telescopic shock absorber |

||||

|

Rear (quantity) |

|

3+2 |

6+5 |

|||

|

Fuel system |

||||||

|

Fuel Type |

|

diesel |

||||

|

Fuel Tank Capacity |

|

75L |

100L |

100L |

100L |

|

|

Brake System |

||||||

|

service |

|

drum brake, vacuum servo hydraulic, (ABS optional) |

||||

|

Parking |

|

mechanical parking brake |

||||

|

Tires |

||||||

|

Front Tire |

|

7.00R15,10PR |

6.50R16,10PR |

7.00R16,14PR |

7.00R16,14PR |

|

|

Rear Tire |

|

7.00R15,10PR |

6.50R16,10PR |

7.00R16,14PR |

7.00R16,14PR |

|

|

Electrical System |

||||||

|

Battery |

|

12V 70A; parallel connection |

||||

|

Alternator |

|

12V 60A |

||||

|

Performance |

||||||

|

Max. Speed |

(km/h) |

98 |

98 |

98-105 |

98-105 |

|

|

Min. Ground Clearance |

(mm) |

≥190 |

||||

|

Min. Turning Radius |

(m) |

10.4 |

12 |

13.6 |

15.2 |

|

|

Approaching/Departure Angle |

(°) |

24/20 |

24/16 |

24/16 |

24/14 |

|

|

Configurations |

||||||

|

A/C |

|

● |

● |

● |

● |

|

|

Power Steering |

|

● |

● |

● |

● |

|

|

Radio |

|

● |

● |

● |

● |

|

|

Spare Tire&tool kit |

|

● |

● |

● |

● |

|

|

Safety Belt |

|

● |

● |

● |

● |

|

|

ABS |

|

○ |

○ |

○ |

○ |

|

|

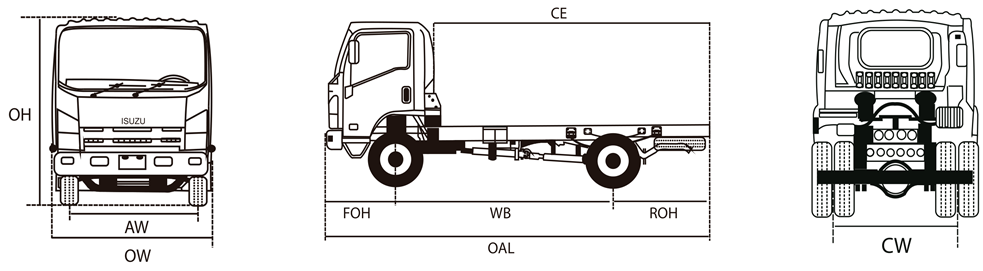

Dimensions |

|||||

|

Wheelbase WB |

(mm) |

2490 |

2765 |

3360 |

3815 |

|

Overall Length OAL |

(mm) |

4605 |

5230 |

5900 |

6665 |

|

Overall Width OW |

(mm) |

1695 |

1860 |

1880 |

1880 |

|

Overall Height OH |

(mm) |

2120 |

2180 |

2200 |

2220 |

|

Front Overhang FOH |

(mm) |

1015 |

1015 |

1015 |

1015 |

|

Rear Overhang ROH |

(mm) |

1100 |

1450 |

1525 |

1835 |

|

Front Tread AW |

(mm) |

1385 |

1377 |

1504 |

1504 |

|

Rear Tread CW |

(mm) |

1395 |

1425 |

1425 |

1425 |

|

Remark: |

|||||

|

1. ● means standard configuration. |

|||||

Why choose ISUZU Giga Fire Fighting Trucks from POWERSTAR TRUCKS INDUSTRY CO., LIMITED?

ISUZU truck chassis is a truck chassis produced by Japan's Isuzu Company and is widely used in the modification of various special vehicles. The ISUZU truck chassis features reliable performance and durable construction, providing a solid foundation for vehicle modifications. The following are common modification types of ISUZU truck chassis:

1. ISUZU Cargo Trucks: ISUZU truck chassis can be used to modify various types of trucks, including flatbed trucks, vans, tank trucks, etc. Modified trucks can be customized according to different needs and cargo characteristics to meet cargo transportation requirements.

2. ISUZU Rescue truck: ISUZU truck chassis is also used to modify various rescue vehicles, such as ambulances, fire trucks and road rescue vehicles. Combined with the reliability and stability of the ISUZU truck chassis, the modified rescue vehicle can respond quickly and perform various emergency rescue tasks.

3. ISUZU Sanitation truck: ISUZU truck chassis is suitable for modifying various types of sanitation vehicles, such as garbage trucks, sprinkler trucks, and road sweepers. The modified sanitation vehicles have powerful cleaning and processing capabilities and can effectively maintain and improve the urban environment.

4. Isuzu Tank truck: ISUZU truck chassis can be used to modify various tank trucks, such as fuel tank trucks, chemical transport trucks, etc. The modified tank truck has a solid structure, making it safer and more reliable to store and transport liquid or gaseous substances.

5. Isuzu Engineering vehicles: ISUZU truck chassis can also be used to modify various engineering vehicles, such as concrete mixer trucks, crane trucks, and excavator trucks. These construction vehicles utilize the stability and load-bearing capacity of the ISUZU truck chassis to play an important role at construction sites and other engineering sites.