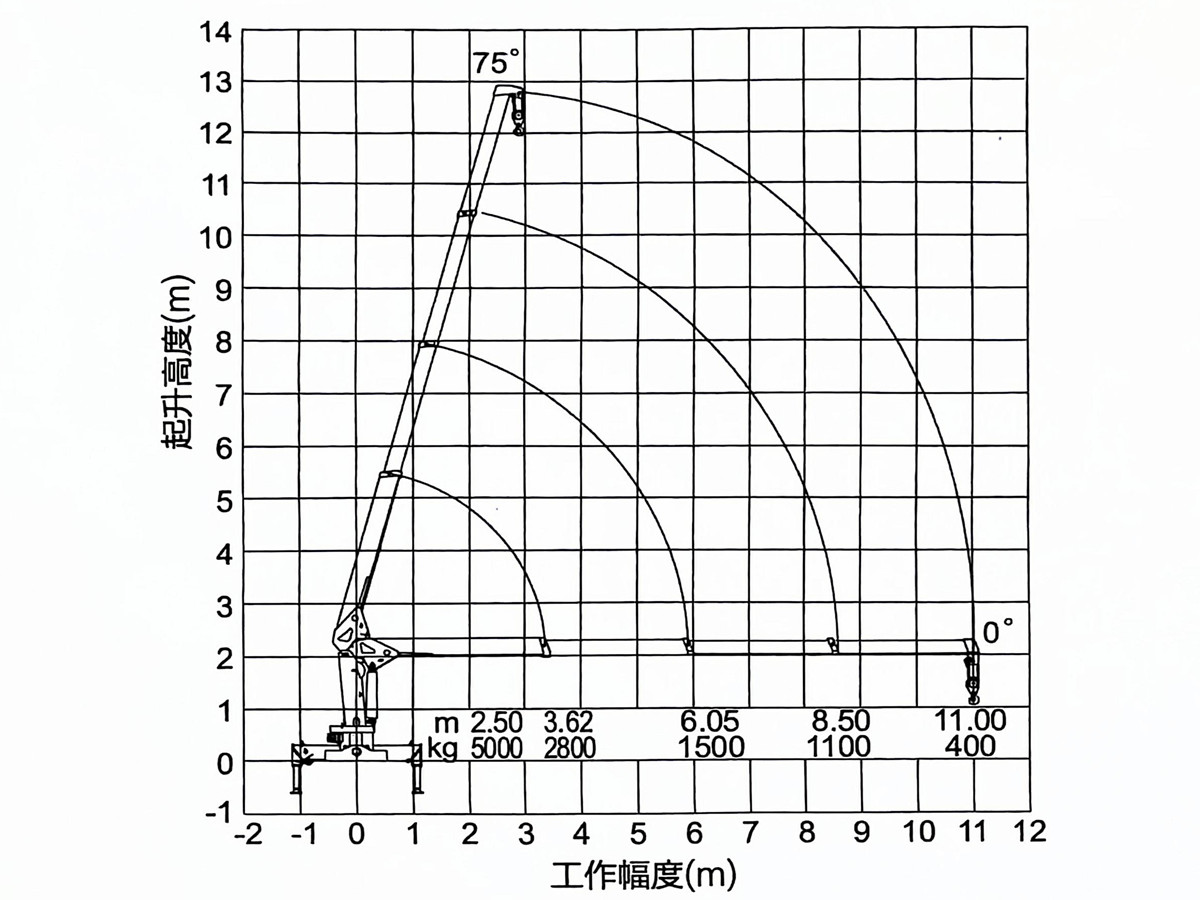

The ISUZU GIGA truck-mounted crane is a special vehicle developed on the ISUZU GIGA 6 wheeler chassis. It is equipped with an XCMG telescopic boom crane with stable performance, a rated lifting capacity of 5 tons, a large working range, and a maximum lifting height of up to 12 meters. The truck is equipped with an ISUZU 380HP diesel engine with strong power. The operation interface design is simple and easy to operate, and it is equipped with multiple safety protection devices. This vehicle is suitable for a variety of operating scenarios and meets the various needs of users.

Work capacity:

5000 kgTruck model:

PT5050JSQEngine power:

380 HPEngine type:

6UZ1-TCG61Axle drive:

4×2Gear box:

FAST 12-speed, manualRemarks:

ISUZU GIGA 6 wheeler chassis, XCMG telescopic boom craneThe ISUZU truck-mounted crane, also named ISUZU boom crane truck, ISUZU truck with crane, is a special vehicle used for cargo loading, unloading and transportation. It is usually equipped with a crane and transport devices that can transport the cargo to the destination after loading it.

ISUZU GIGA truck mouonted hydraulic crane consists of ISUZU GIGA chassis, crane, cargo box and operating system. The chassis is the foundation of the vehicle and has good load-bearing capacity and driving stability. The crane is the core part of the vehicle. It can realize the lifting, rotation and pitching of goods to facilitate the loading and unloading. A cargo box is a container used to carry goods, and can be selected in different sizes and shapes according to needs. The operating system is a device that controls the movements of the crane and cargo box, usually controlled by the driver through the operating valves.

ISUZU GIGA boom crane trucks are widely used in logistics, construction, road construction, rescue and other fields. It can quickly load and unload goods, improve transportation efficiency, reduce labor costs, and can operate in complex environments. In addition, ISUZU truck with cranes can also be used for rescue and emergency operations, such as quickly transporting relief supplies and equipment after natural disasters such as earthquakes and floods.

Product Specifications

|

Product model |

PT5050JSQ |

|

|

Driving type |

4×2, left hand drive |

|

|

Engine |

Brand |

ISUZU |

|

Model |

6UZ1-TCG61 |

|

|

Type |

6-cylinder, in-line, turbocharged and intercooled |

|

|

Maximum output |

380HP (279KW) |

|

|

Maximum torque |

1800 Nm |

|

|

Rated speed |

2000 rpm |

|

|

Displacement |

9839 ml |

|

|

Transmission |

Brand |

FAST |

|

Type |

12 speed, 12 forwards and 2 reverse, manual |

|

|

Axle |

Front |

7500 kg loading capacity |

|

Rear |

13000 kg loading capacity |

|

|

Chassis |

Frame |

U-profile parallel ladder frame and reinforced subframe, all cold riveted cross members, manganese steel |

|

Front suspension |

leaf spring |

|

|

Rear suspension |

leaf spring |

|

|

Fuel tank |

400 L capacity with locking cap |

|

|

Wheels & Tyres |

Tire size |

295/80R22.5 |

|

Number |

6+1 pcs |

|

|

Cabin |

Type |

Single cab, with sleeper, A/C, ABS |

|

Seats |

2 |

|

|

Dimensions mm |

Wheel base |

4600 mm |

|

Overall length |

9000 mm |

|

|

Overall width |

2500 mm |

|

|

Overall height |

3750 mm |

|

|

Cargo box dimension |

5000×2500X550 mm |

|

|

Parameter of Crane |

Brand |

XCMG |

|

Model |

KSQS125-4 |

|

|

Max lifting capacity |

5000 KG |

|

|

Max lifting moment |

12.5 KN.M |

|

|

Recommended power |

18 KW |

|

|

Max oil flow of hydraulic system |

40 L/M |

|

|

Max pressure of hydraulic system |

22 Mpa |

|

|

Oil tank capacity |

90 L |

|

|

Crane weight |

2230 KG |

|

|

Rotation angle |

360 degree |

|

|

Installation space |

900 mm |

|

|

Weight kg |

Gross vehicle weight |

22000 kg |

|

Curb weight |

12500 kg |

|

|

Rated Loading Capacity |

10000 kg |

|

|

|

Product Structure

The main mechanisms and systems of ISUZU truck-mounted crane

● Control mechanism

The control mechanism of ISUZU crane truck consists of a control linkage mechanism and a control valve.

The control valve is a superimposed directional control valve, which is divided into an upper control valve and a lower control valve. The upper control valve is composed of four single-chip reversing valves and a relief valve; the lower control valve is composed of a single-chip reversing valve, four single selector valves and a relief valve. The upper control valve controls lifting, luffing, telescopic, and rotation respectively. The lower control valve controls the horizontal expansion and contraction of the outriggers and the vertical expansion and contraction respectively. There is no interlocking between the various mechanisms, and each mechanism can be operated simultaneously. Both sides can be controlled by operating the linkage mechanism.

● Hoisting mechanism

The lifting and winching mechanism consists of a hydraulic motor, a winch reducer, a drum, a wire rope and a hook.

The winch motor is driven by high-pressure oil, and the output shaft produces rotational motion. After being decelerated by the reducer, the small gear drives the large gear to rotate. The large gear is connected to the drum through bolts, driving the drum to rotate, thereby winding the wire rope around the drum or releasing the wire rope from the drum to drive the hook and weight up or down.

There is a built-in brake in the reducer to ensure that heavy objects can stay at any position in the air.

● Crane and telescopic mechanism

It mainly consists of boom, telescopic cylinder, wire rope group, balance valve, etc. The boom is a pentagonal structure formed by welding high-strength low-alloy steel, with a total of four sections. Special nylon sliders are installed on the head and tail of each section arm to support and reduce friction. The expansion and contraction of the boom is carried out through a telescopic cylinder and a steel wire rope. The piston rod of the telescopic cylinder is articulated with the first section of boom, and the cylinder barrel is articulated with the second section. The telescopic expansion directly drives the second section to expand and contract, and each wire rope group simultaneously drives the third and fourth section.

● Rotary mechanism

The rotary mechanism is composed of a hydraulic motor, a planetary reducer, a slewing bearing, etc.

The hydraulic motor rotates under the drive of high-pressure oil. After being decelerated by the planetary reducer, it drives the pinion gear to rotate. The pinion gear meshes with the teeth of the large ring gear on the outer ring of the slewing bearing, driving the large ring gear to rotate; the large ring gear and the column are fixed with bolts, thus driving the column and the boom to rotate together.

There is a normally closed disc brake in the planetary reducer, which can ensure that the output pinion will not swing randomly, and its braking ability can be guaranteed even if it stops on a certain slope. When high-pressure oil flows into the hydraulic motor, it passes through a shuttle valve and enters the brake cylinder to open the brake, and the pinion can rotate normally.

●Hydraulic system

The movements of the working part of ISUZU boom crane truck, including lifting, luffing, telescopic, slewing and lifting of the outriggers, are all driven by hydraulics. The high-pressure oil discharged from the oil pump is distributed through the control valve to the hydraulic motor or hydraulic cylinder to perform various actions.

The hydraulically controlled one-way valve in the lower control valve blocks the oil in the rod cavity of the horizontal cylinder of the outrigger, ensuring that the horizontal outrigger will not extend when driving, ensuring driving safety.

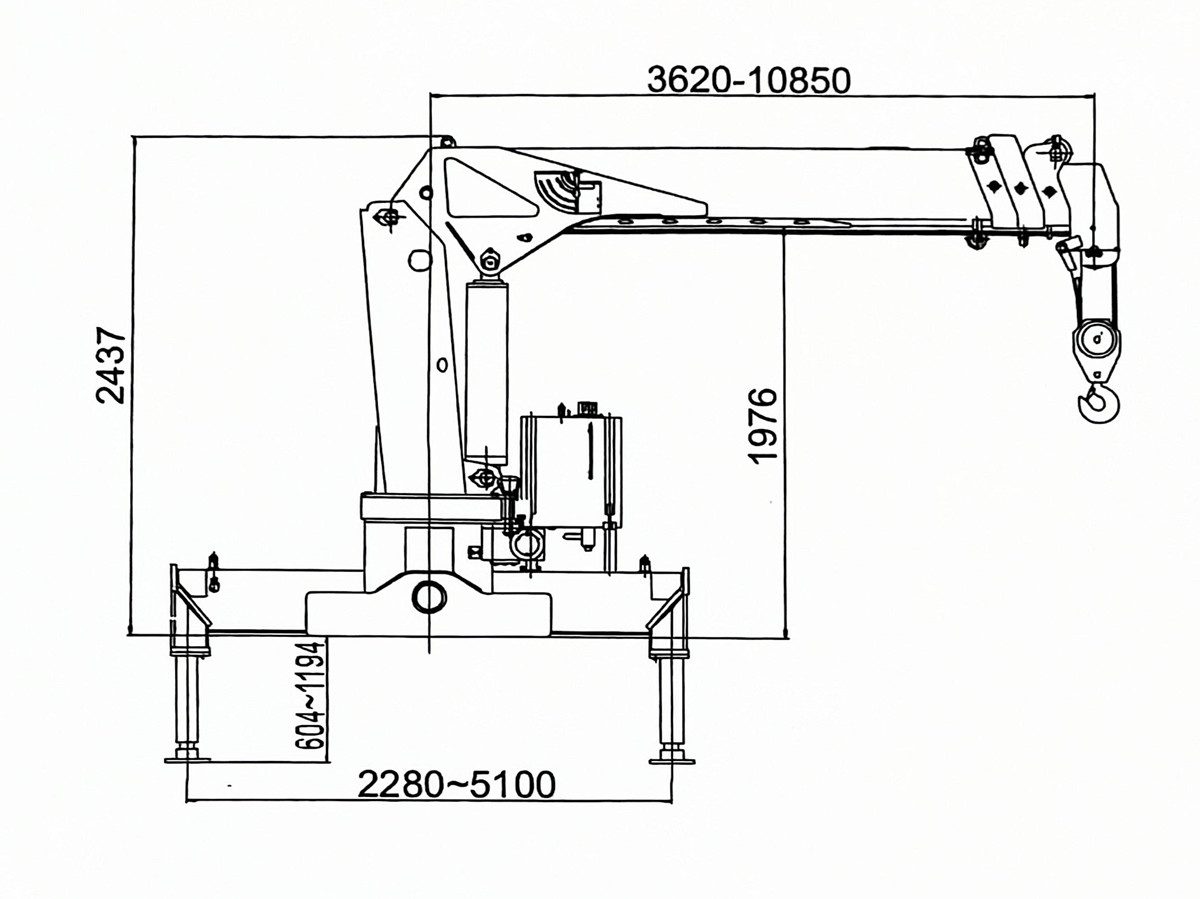

● Outriggers

The ISUZU truck with crane has H-shaped outriggers. The horizontal movement of the outriggers is realized by the expansion and contraction of the horizontal oil cylinder, and the lifting and lowering of the outriggers is driven by the vertical oil cylinder. A hydraulic lock is installed on the vertical cylinder of the outrigger, which can reliably prevent the outrigger piston rod from extending when driving.