Isuzu sewage suction trucks are vehicles designed and manufactured specifically for the complex pipe networks and surrounding operating environments in cities around the world. Its functions include high-pressure washing, pipe clearing, sewage suction and feces suction, transportation back filling, etc. It can not only handle solid materials such as sludge, gravel, and bricks in conventional operations, but also clean small rivers, and has the function of quick and efficient dredging and rescue. Therefore, it is widely used in urban sanitation, emergency and disaster relief, and waste treatment in special petrochemical industries.

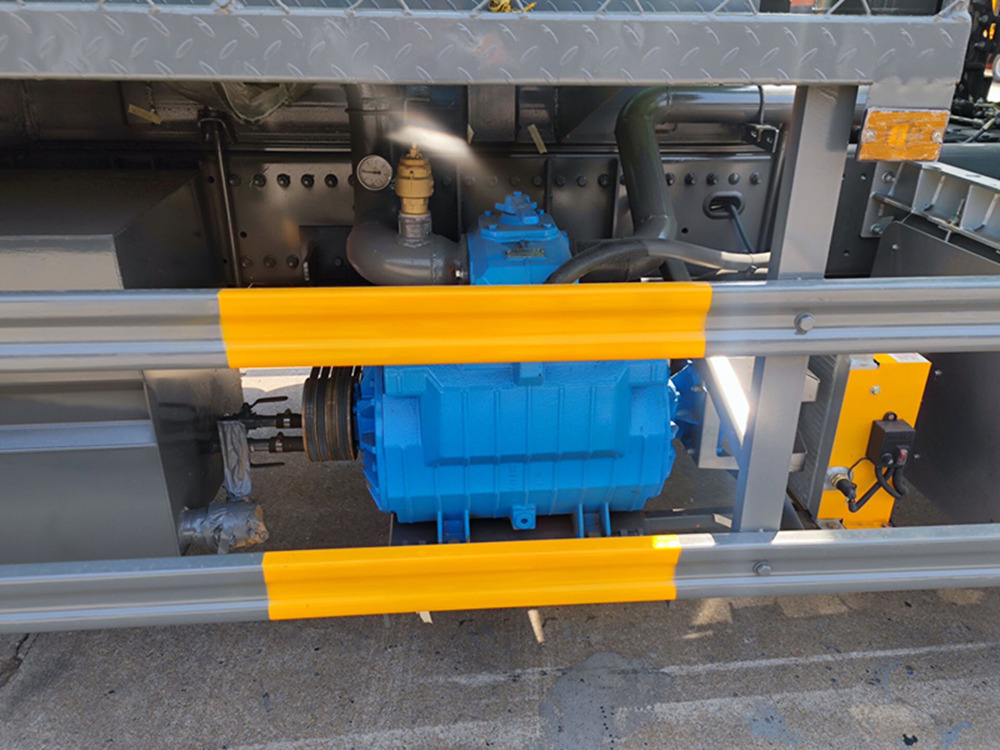

The special parts of Isuzu sewage suction trucks include power take-off, transmission shaft, vacuum sewage suction pump, pressure tank, hydraulic system, pipe network system, vacuum pressure gauge, fecal viewing window and hand washing device, etc. It is equipped with a high-power vacuum sewage pump and a high-quality hydraulic system. The tank head is die-cast in one step and can be opened from the rear and automatically unloaded. The dirt in the tank can be poured directly through the back cover, which has the characteristics of high vacuum degree, large tonnage and high efficiency.

As Isuzu sewage suction trucks are used more and more frequently, they play a positive role in reducing environmental pollution. Therefore, you should pay attention to the following points in terms of maintenance:

1. Reasonably determine the maintenance cycle: scientifically determine the interval mileage of various maintenance operations based on the vehicle's technical condition and operating environment to maintain the vehicle's good technical condition and avoid unnecessary failures.

2. Make full use of free inspections: Car owners can use free inspection activities to conduct a comprehensive physical examination of the vehicle, promptly discover and eliminate potential faults, and avoid unnecessary faults in the future.

3. Minimize disassembly and repair of the assembly: In order to prevent the vehicle from entering the maintenance period and minimize the disassembly and repair of the assembly, advanced maintenance equipment and technology can be used for disassembly-free maintenance, speeding up maintenance and reducing damage.

4. Use fuel and lubricants rationally: It is very important to choose the appropriate fuel and lubricants. Choosing good quality fuel and lubricants can meet vehicle requirements, improve engine efficiency, and extend engine life.

5. Replace hydraulic oil regularly: Use an oil-water separator to separate the hydraulic oil, and reuse the used hydraulic oil as lubricating oil for the vacuum pump of the sewage suction truck. However, the separated water needs to be drained, otherwise it may enter the pump and cause failure.

6. Check and maintain the anti-overflow valve: The anti-overflow valve prevents sewage from overflowing into the vacuum pump when the tank is full. Therefore, the working status of the anti-overflow valve should be checked frequently when the sewage suction truck is working to ensure its normal operation.

7. Clean the rear tank door sealing ring: Due to long-term use, dirt may accumulate inside the rear tank door, so the inside should be cleaned and an appropriate amount of grease added every 6 months. At the same time, regularly check the sealing ring of the rear tank door. If there is leakage, it needs to be replaced in time.

The above are the precautions for the maintenance of Isuzu sewage suction trucks. I hope it will be helpful to you.