Many customers purchased our Isuzu sewage pump truck, but after using it for two years, there was a big difference. Some sewage pump trucks begin to experience high maintenance costs, while others maintain optimal performance. Why is there such a big difference? Some people say that the quality of the sewage pump truck may be different, while others say that the driver's operation is different. Everyone is right, the age, quality and operation of the sewage pump truck will all affect the difference. The best choice, of course, is to buy our Isuzu sewage pump truck with guaranteed after-sales service. But once the sewage pump truck is purchased, its quality has been determined and cannot be changed.

Therefore, we can extend the service life of Isuzu sewage pump truck through correct and reasonable use and maintenance. We recommend the following measures:

1. Regularly change the engine oil: Regularly changing the engine oil can extend the service life of the engine. Over time, the engine oil will become dirty, affecting the lubrication effect and accelerating engine wear. Synthetic motor oil lasts longer, but can also stain. Changing your engine oil regularly and using the proper grade of oil will keep your engine clean and well lubricated. At the same time, pay attention to regularly checking the engine oil level and replenishing the engine oil in time.

2. Ensure that various lubricants are clean and sufficient: Isuzu sewage pump truck's various lubricants are very important to the vehicle, such as automatic transmission oil, brake oil, steering oil, engine coolant, etc. Over time, these lubricants can evaporate, leak, or degrade in quality. Please replace and replenish the lubricating oil in time to keep the sewage pump truck running well. Various lubricant types and replacement intervals can be found in the user manual of the sewage pump truck chassis.

3. Detect problems early: Finding and solving small problems before they happen can prevent problems before they occur and save repair costs. Always pay attention to whether the sewage suction truck has abnormal behaviors and sounds, such as warning lights that are always on, excessive engine temperature, oil leakage, abnormal sounds and odors when braking or bumping, uncomfortable driving feeling, poor acceleration, etc. These small signs need to be checked in time.

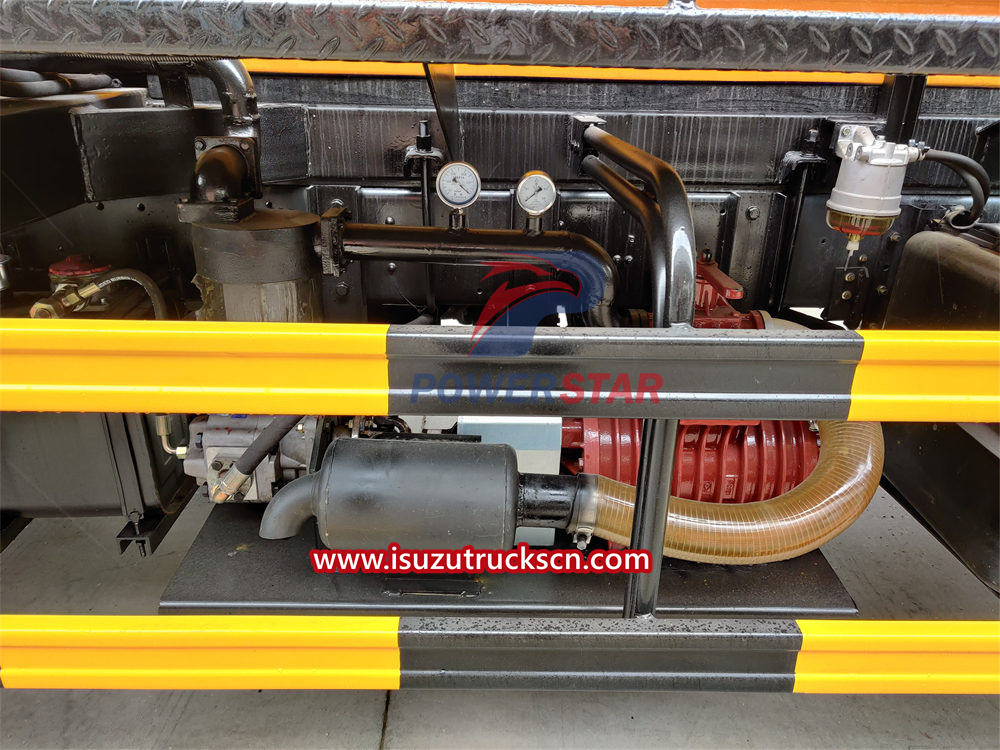

4. Pay attention to maintaining the car body: If the location is humid, the metal of the car body is easy to rust. Please perform anti-rust maintenance on the brakes, oil supply and chassis parts of the sewage suction truck in time. Clean the sewage suction truck regularly to prevent corrosion. Replace wipers at least every two years. Repair scratches on the car body promptly to avoid exposure of metal causing rust.

5. Keep the interior of the vehicle dry and tidy: There are many electronic devices and wires inside the sewage pump truck, so it is very important to keep the interior of the vehicle dry and tidy. Avoid getting moisture into electronic equipment, as water can cause damage to the equipment. Keeping your car's interior clean and dry will keep it smelling fresh. Replace the air conditioning filter regularly to avoid odors. Turn off unnecessary in-car functions to reduce load.

6. Maintain tires regularly: Check tire pressure regularly. Adequate air pressure can extend tire service life and reduce fuel consumption. Regularly changing the left and right tire positions can evenly wear the tires and extend their service life.

7. Drive smoothly: Avoid sudden acceleration and braking, which will accelerate the wear of various parts. Choose as smooth a ride as possible. Make good use of the highway. If you often drive short distances, you need to drive on the highway regularly to allow the engine to fully warm up and remove moisture.

8. Regular debugging and maintenance: In addition to regular oil changes, other maintenance work should also be paid attention to. For example, replace your air filter every 10,000 to 20,000 miles. Replace spark plugs and other parts every 60,000 to 90,000 miles; bad spark plugs can lead to increased fuel consumption, reduced engine power and ignition coil failure. Ignition coils also need to be replaced regularly. For some sewage pump trucks, the valve clearance needs to be adjusted regularly. The timing belt of many sewage pump trucks also needs to be replaced regularly, along with the water pump.

9. Familiar with the sewage pump truck: As a special-purpose vehicle, the Isuzu sewage pump truck has its own operating procedures. We have specially written an operation manual for the Isuzu sewage pump truck to introduce in detail the operating procedures and working principles of the Isuzu sewage pump truck when suctioning and discharging sewage. Familiarity with the operating manual will allow you to better use your Isuzu sewage pump truck and extend its service life.