Isuzu vacuum truck is a sanitation vehicle specially used to collect, transfer and clean and transport sludge, sewage, etc. Its main purpose is to avoid secondary pollution of the environment by these pollutants. Isuzu vacuum truck has the function of self-priming and self-discharging, can work quickly and efficiently, and has a large loading capacity and convenient transportation method. They are usually used in urban sanitation, highways, community sanitation, landscaping and green belts and other fields. This article will introduce the Isuzu vacuum truck in detail.

Isuzu vacuum truck operating precautions:

1. Keep the vacuum pump of the sewage suction truck at an appropriate rotation speed.

If the vacuum pump speed is too high, the rotor will heat up; if the speed is too low, it will cause engine knocking, causing additional shock to the components, affecting the service life. For a suitable working speed, adjust the maximum adjustment position of the hand throttle in advance. The suitable rotation speed of the sewage suction truck pump type xd-44 is 500-600 rpm.

2. The Isuzu vacuum truck is hydraulically lifted and dumped on flat ground.

Isuzu vacuum truck is strictly prohibited to be hydraulically lifted and dumped on a sloping road. If it is hydraulically lifted and dumped on a sloping road, the weight of the vehicle body will be tilted to one place due to the uneven road surface, causing distortion and deformation of the components there, and may easily cause a rollover accident.

3. When hydraulically lifting the sewage suction truck, open the rear door window first.

The rear door of the tank should be opened before hydraulic lifting to unload sludge. It is strictly prohibited to hydraulically lift the tank body of the sewage suction truck before opening the rear door of the tank, because the center of gravity will shift backward after lifting, which may cause the risk of overturning.

4. Isuzu vacuum truck clutch oil pump power take-off and vacuum pump power take-off power take-off.

The operator should control the accelerator, make the engine idle, and fully step on the clutch pedal. After engaging the power take-off to take power, the driver should slowly release the clutch pedal. Do not hang up the power take-off without depressing the clutch, otherwise the power take-off gear will hit the running gearbox gear, causing damage to both gears. The power take-off lever of the sewage suction truck must be placed in the middle position when the vehicle is driving.

5. Do not use Isuzu vacuum truck to suck in or transport waste oil and dangerous goods.

When entering or repairing the sludge tank of a sewage suction truck while the sludge tank is hydraulically lifted, support rods and safety stops must be used. When transporting sewage, a manual rear door tank clamping device must be used. Since there is no anti-wave plate in the tank and the center of gravity is high, the vehicle must drive at a medium or low speed and cannot make sharp turns or brakes.

2.Isuzu vacuum truck suction operation method:

1). Before inhaling the Isuzu vacuum truck, prepare to close the rear door of the tank body of the sewage suction truck and observe whether the lubricating oil of the vacuum pump oil and gas separator is normal.

2). Operation sequence:

a. Depress the clutch pedal, push the power take-off lever to run the vacuum pump of the sewage suction truck, and then slowly release the clutch pedal.

b. Turn on the sewage suction truck alarm switch in the cab.

c. Pull the throttle handle to the maximum position, observe the tachometer, and make it reach 500-600 rpm (it has been adjusted at the factory).

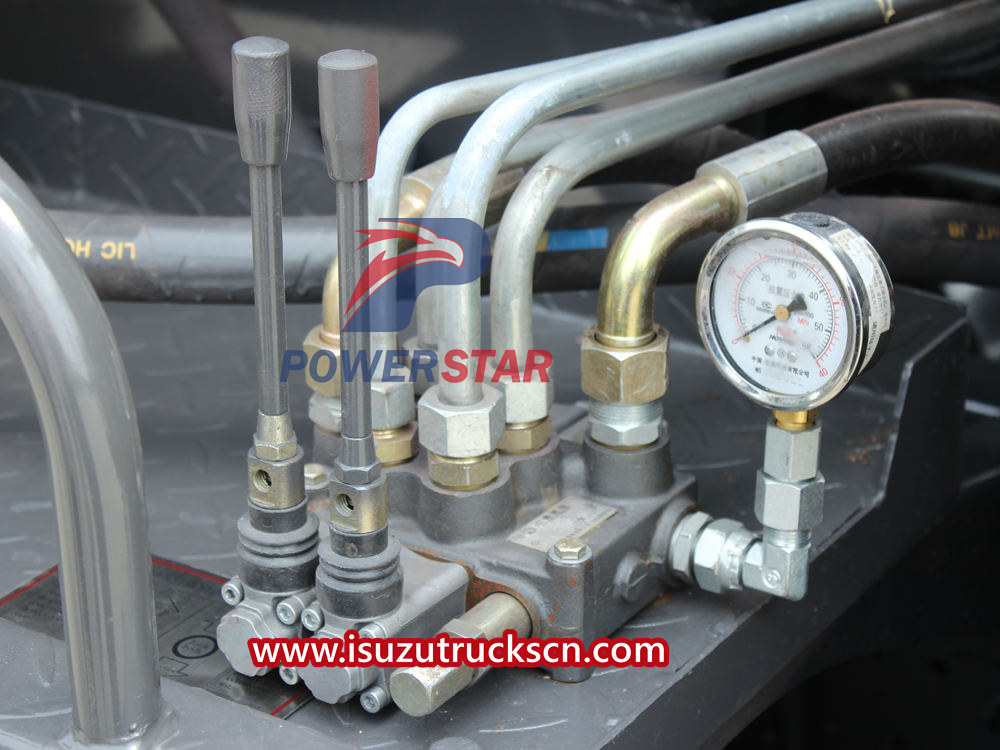

d. Place the four-way valve switching handle in the suction position, and check whether the air discharged from the trachea is correct, whether there is any sound when the vacuum pump is running, and whether the vacuum gauge is normal.

e. Remove the sewage suction hose from the sewage suction truck and put it into the sediment well. In order to keep the sewage suction hose in a straight line or freely bent state, the parking position should be fully considered.

3). Precautions for Isuzu vacuum truck suction operation:

a. Stones larger than 50mm, cotton yarn, leaves and other impurities will block the straw. So do not inhale and remove frequently.

b. When the vacuum gauge reading reaches 65-80 kPa, fully open the ball valve of the sewage suction truck. The half-open state can easily damage the valve core. When inhaling sludge, the suction pipe should be moved frequently. When inhaling high-viscosity sludge, occasionally inhaling air and water can improve the pollution efficiency.

3: Discharge method of Isuzu vacuum truck: After the mud and water are separated, open the drainage ball valve, drain the sewage and repeat the suction of mud. You can also pressurize and drain quickly. The operation method is as follows.

1). Place the four-way valve switching lever in the "neutral" position, and then place the drainage ball valve in the "open" position, so that sewage can be discharged reliably by gravity.

2). Switch the four-way valve of the sewage suction truck to the discharge position, and the vacuum pump continues to work, then the compressed air sewage flowing into the tank will be quickly discharged.

3). When discharging pressure, the discharge ball valve should be opened first, and then the four-way ball valve can be moved to the discharge position to avoid excessive pressure in the tank, causing accidents and affecting the tank door seal.

4:Isuzu vacuum truck sludge discharge method

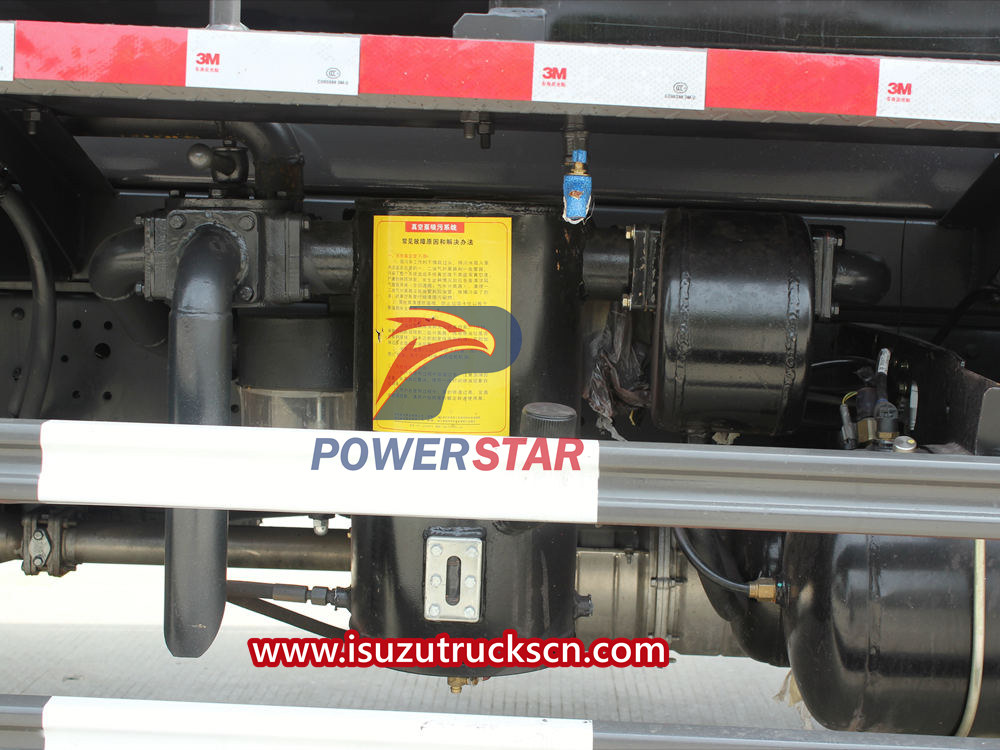

1).Depress the clutch, move the pneumatic reversing valve to the open position, or push the power take-off lever to run the oil pump.

2).Open the tank door ball valve, discharge part of the sewage, and reduce the pressure inside the tank to communicate with the atmosphere.

3).Loosen the tank door locking device, loosen the handle and completely pull out the screw.

4).Set the tank door opening and closing lever of the manual reversing valve of the sewage suction truck to "open". Before opening, make sure that the pressure in the tank is equal to atmospheric pressure. If the tank door is opened under negative pressure, the tank door will be damaged. Seals and cylinders.

5). Place the hydraulic lift valve stem of the manual reversing valve in the "up" position.

6). For the recovery operation after discharging the sludge, place the hydraulic cylinder operating lever in the "lowering" position, and check the following after safely descending:

a. Check whether there is dirt on the tank door flange and sealing ring, and scrub them clean with a brush.

b. Set the tank door opening and closing lever to "close" and close the door safely.

c. Insert the screw of the clamping device into the screw hole on the side of the tank and turn the handle until the rear tank door is pressed tightly.