What is the main components of isuzu 4x4 off road garbage compactor truck

The Isuzu off-road garbage compactor truck is a highly efficient and reliable waste management vehicle. With a range of advantages, it serves the purpose of waste collection and transportation effectively.

Firstly, the Isuzu off-road garbage compactor

truck features a robust design and strong construction, enabling it to

handle the rigorous demands of off-road terrains. It has excellent

maneuverability and off-road capabilities, allowing it to navigate

through tough and uneven terrains effortlessly. This ensures that waste

collection can be efficiently carried out in remote or challenging

areas.

The Isuzu 4*4 compactor truck offers a high compaction ratio. With its advanced compression system, it can effectively compress and compact the waste inside the vehicle. This results in a significant reduction in the volume of waste, maximizing the truck’s storage capacity and reducing the number of trips required for disposal.

Furthermore, the Isuzu off-road garbage compactor truck is equipped with state-of-the-art technology and safety features. It has a user-friendly control system that allows for easy operation and monitoring. The truck is also designed with safety in mind, featuring stability control mechanisms and advanced braking systems to ensure safe operation during off-road missions.

The operator should fully understand Whole Structure and Working Principle for ISUZU Garbage Compactor Truck before any operation. Only trained person can operate this vehicle properly and to prevent unnecessary accidents and equipment damage.

Japan isuzu 4x4 drive off road garbage compactor truck

ⅰ,How are the Isuzu 4*4 drive Garbage Compactor trucks working?

The ISUZU off road Garbage Compactor Truck makes use of the special power take off (PTO) to get power from the engine, and then transfer the power to the Gear Pump so to rotate the pump. The pump start working to transfer hydraulic oil to cylinders through pipelines, and cylinders working to make all garbage trucks equipment working, including tailgate, push plate, slide plate, scraper and tilting device. And then realize all function of the garbage compactor truck.

ⅱ,What is the main component for Isuzu 4 wheel drive garbage compactor trucktruck?

The garbage compactor truck is refitted based on the ISUZU 600P 4x4 chassis. The refit part includes garbage collection assembly, actuator device and operation system.

Garbage collection assembly: High Strength steel material tanker body for garbage storage, with tailgate, slide plate, scraper, push plate and tilting device to realize garbage loading and unloading working.

Actuator device: includes power take off, drive line, etc., which can pass the power from the chassis to the gear pump.

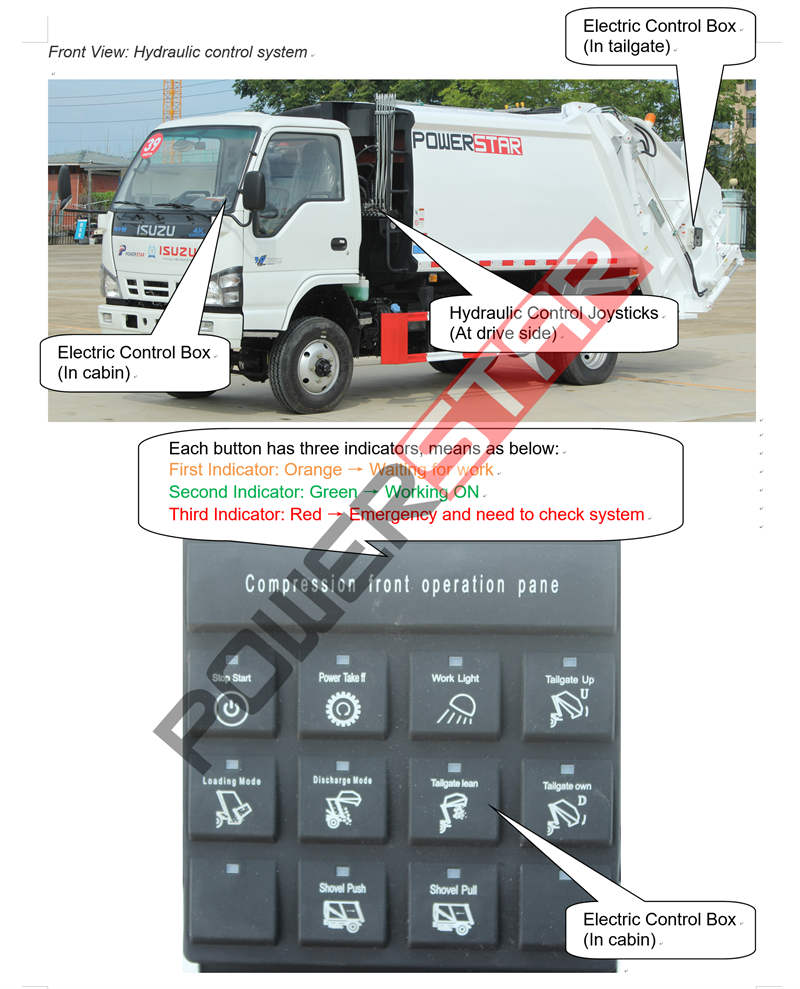

Operation system: including CAN Electric control system (Main control box in cabin & Rear control box at side of tailgate) and Hydraulic Joystick control system, this helps come to all special functions’ convert.

ⅲ, How to operate Isuzu 4x4 drive garbage compactor trucks? (Very Important)

1.1 Precautions for Truck Usage

2.1 Precautions before use

1. Prepare the truck before departure according to the requirements of the chassis instruction;

2. Check truck lights and ensure that they can work normally;

3. The tailgate should be in the state of falling and lock-up and the push-shovel cylinder should be in the position of maximum extension;

4. The fuel pump should be able to rotate normally after installing the PTO;

5. Since the viscosity of hydraulic oil will increase in low temperature, the operator shall run the compressing-filling and bucket-lifting mechanism in non-loaded condition for several times before loading operation.

Japan isuzu 4*4 drive off road garbage compactor truck with hopper system.

2.2 Precaution in use

1. The operation site should be spacious, flat and open;

2. Irrelevant personnel shall never approach the truck, especially the rear during the operation;

3. The garbage should be put into the filling bucket evenly, and no garbage shall be concentrated on one side, which may shift the center of gravity of the truck, or piled too much garbage along the edge of the filling bucket, which may affect the compressing and filling of garbage and lead to uneven distribution of garbage in the garbage can;

4. Attention should be paid to the compressing and filling operation, and in case of any large garbage that are too large to be compressed, the operator shall stop in time, and then continue to work after clearing such garbage, otherwise, the working equipment of the truck may be jeopardized;

5. When lifting and dropping the pre-compressor during the unloading operation, it’s necessary to ensure the safety of surroundings, and carry out operation carefully. The pre-compressor shall not be lifted up on the slope; otherwise the center of gravity may easily be shifted backward, thus causing overturning accident;

6. After unloading, the joint surface of the garbage can and the pre-compressor shall be cleaned to ensure that the joint surface is well sealed and avoid damaging the rubber seal due to sharp objects or hard objects in the garbage.

7. The truck shall be allowed to work only after the pre-compressor has fallen down and lock-up.

2.3 Precautions for maintenance after use

1. Do a good job of maintenance according to this instruction and chassis manual in time;

2. The washers at the sewage outlet of blow down apparatus of the garbage can shall be cleaned every day, especially after discharging the sewage, and the residue on the gasket shall be cleaned, otherwise it is easy to cause the damage of the blow down apparatus or the seal failure;

3. Do not spray water directly on electrical components and fuel tanks when washing the truck;

4. No one is allowed to stand or walk under the pre-compressor after it is lifted. It is necessary to hold up the pre-compressor with jack stay and stand up to it with solid supports when lifting up it for maintenance, thus preventing disastrous accidents;

5. During overhaul, no one shall throw, collide, and strike the truck, thus preventing parts from damage, deformation and scratches. When dismantling the hydraulic system, cleaning is necessary;

6. When dismantling the hydraulic system or electrical control system, the pre-compressor should be in the falling position, and the scraper and slider should be put down slowly or fixed, otherwise the any sudden movement of pre-compressor or scraper and slider will damage the equipment or lead to other disastrous accidents;

7. Loading and unloading operations are completed automatically, and no one shall adjust it without permission. When the speed of PTO is too high, PTO or fuel pump power unit will be damaged, and when the speed is too low, the operation efficiency will be affected;

8. The pressure valve spring has been properly adjusted before delivery, and it is strictly forbidden to adjust it without permission. In case of any obvious reduction in loading capacity, it should be repaired at the designated maintenance point;

9. For garbage trucks equipped with external motor as the power system, the opening-closing duration of the scraper is adjusted according to the flow rate of the system. When working via applying the chassis engine, the opening-closing duration of the scraper is shorter than that of the motor power system, and it is normal that the scraper pauses shortly when the scraper opens and closes.

Isuzu 600P cabin with 4*4 wheeler garbage compactor truck

2.4 Cautions for garbage trucks storage

1. The truck should be stored in the garage featured with excellent ventilation, dry and clean environment, free from corrosive medium. In case of open storage, the truck shall be covered with tarpaulin;

2. When the truck is stored, the chassis gearbox should be placed in the neutral position, PTO should be disconnected, and the cylinder should be in a retracted state.

Isuzu 4*4 drive garbage compactor truck with POWERSTAR upper body.

1.2 Ready to work

(If idle for a long time, please keep the truck engine run for a few minutes. Also, should ensure fuel tank and water tank are enough.)