Isuzu oil tank truck is a vehicle specially used to transport various types of flammable and explosive oils, chemicals and other dangerous goods. Isuzu oil tank truck needs to pay special attention to safety when transporting dangerous goods to prevent dangerous incidents from occurring.

The quality of Isuzu oil tank truck is directly related to the safe transportation and use of oil products, so how to produce qualified Isuzu oil tank truck has become a very important topic. The following will introduce how to produce a qualified Isuzu oil tank truck from five aspects.

Isuzu oil tank truck features:

1.Tank material : 4-6mm thick carbon steel with high quality .

carbon steel and stainless steel or aluminum alloy can be choose.

2.Tank shape: square-round, oval, round;

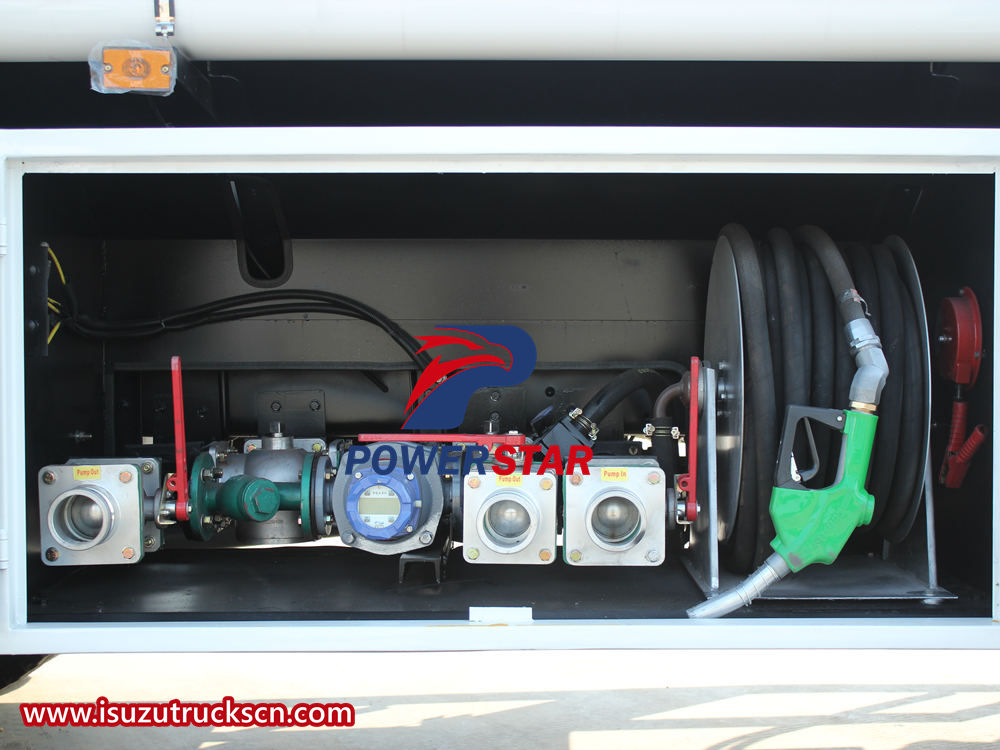

3. Pump : can be choose self-priming pump, gear pump or double pump;

the pump can help the oil pump in and out or self-flow.

4.Special design: can be designed to an independent sub-warehouse to transport different oil with the same time.

15 meters refueling reel (can automatically return to position),

the tank is equipped with many anti-wave boards to keep the tank with high strength, stable center of gravity,

delivery safety and other characteristics in the transportation.

Isuzu fuel truck also known as oil tank truck,fuel tank truck, fuel dispenser truck ,mobile refueling truck, oil transport vehicle,mobile catering truck,mobile refueling truck, oil tanker, oil loading truck, fuel bowser truck,oil tanker, fuel tank truck, oil bowser, fuel oil tanker,oil delivery truck, petroleum service truck, fuel oil storage tank, fuel tanker lorry, refueling tanker truck, crude oil truck,mainly used for the transportation and storage of petroleum derivatives (gasoline, diesel, crude oil, lubricating oil, coal tar and other oils).

|

TECHNICAL SPECIFICATION |

||

|

Main specification |

Chassis brand |

ISUZU |

|

Chassis model |

QL1160VMFRY |

|

|

Overall dimension(L*W*H) |

7500x2500x3500mm |

|

|

Axle No. |

2 |

|

|

|

Drive modle |

4x2, left hand drive |

|

Wheel Base |

4500mm |

|

|

Front Axle loading capacity |

6300kg |

|

|

Rear Axle loading capacity |

13000kg |

|

|

Maximum speed |

95km/h |

|

|

Tyre size |

1000R20, with one spare tyre |

|

|

Tyre number |

6+1 nos |

|

|

Fuel/Engine type: |

Diesel,Vertical in-line, water-cooled, six stroke |

|

|

Engine horse power |

205hp |

|

|

Engine emission standard |

EURO 5 |

|

|

TANKER PARAMETERS |

||

|

Tank volume |

12,000L |

|

|

Compartments |

1 compartment |

|

|

Tank thickness |

5mm body/ endplate 6mm |

|

|

Material of tanker |

Q235B carbon steel 5mm, epoxy paint 3 layer inner surface |

|

|

Standard configuration |

Discharge valve ,1pc each compartment |

|

|

EURO standard manhole with feeding inlet and bulit-in pressure relief valve , 1pc each compartment |

||

|

Oil pump |

||

|

Emergency cutoff device |

||

|

bottom valve (safety valve ),1pc each compartment |

||

|

Other fittings |

Ladder for climbing |

|

|

Walkway, anti-skid |

||

|

Handrail, anti-skid |

||

|

Hose carriers: 2pcs at each side |

||

|

Fire extinguisher: 2Nos, carrier hold |

||

|

Earthing reel, side bumper, 1 set |

||

|

Transport medium |

Diesel oil, gasoline or others |

|

1. Design stage

To produce a qualified Isuzu oil tank truck, design is crucial. The design should take into account the safety, stability and transportation efficiency of the Isuzu oil tank truck. The size, shape, load capacity, material selection and other factors of the vehicle. The design of the tank should take into account the density, corrosiveness, flammability and other factors of the liquid to ensure safe transportation. In addition, the design also needs to take into account the ease of use, maintenance and comfort of the Isuzu oil tank truck.

2. Material selection

Material selection is critical to the quality and service life of Isuzu refueling trucks. For the tank body, materials that are corrosion-resistant, high-pressure resistant, and wear-resistant should be selected, such as stainless steel or aluminum alloy. High-strength, corrosion-resistant, and wear-resistant materials should be selected for the chassis and other structural parts to ensure the stability and durability of the vehicle.

3. Manufacturing stage

During the manufacturing process, relevant manufacturing standards and quality control procedures should be strictly . The first is the welding process. The welding requirements are strict and the weld quality is good to ensure the sealing of the Isuzu mobile fuel truck. The second step is the appearance processing, which requires the car body to be beautiful and smooth to ensure the balance and stability of the car body. At the same time, quality supervision should be strengthened during the manufacturing process to ensure that every link meets standard requirements.

4. Testing phase

After the manufacturing is completed, the Isuzu diesel transfer truck should be fully tested and inspected. Including testing on welding, appearance, sealing and other aspects to ensure that each Isuzu diesel transfer truck meets relevant standards and requirements. This includes pressure testing, tightness testing, vibration testing, etc. During the test, it should be ensured that the Isuzu diesel transfer truck can withstand the predetermined pressure and temperature without leakage or other problems.

5. Certification and Licensing

Isuzu refueling truck needs to go through relevant certification and licensing procedures. This includes vehicle safety certification, environmental certification, fire certification, etc. Only certified and licensed tank trucks are considered qualified Isuzu refueling trucks and can safely transport petroleum products on the road.

In general, producing a qualified Isuzu oil tank truck requires considering many aspects such as design, materials, manufacturing, testing and certification. Only by strictly complying with relevant standards and procedures can the quality and safety of Isuzu oil tank trucks be ensured.