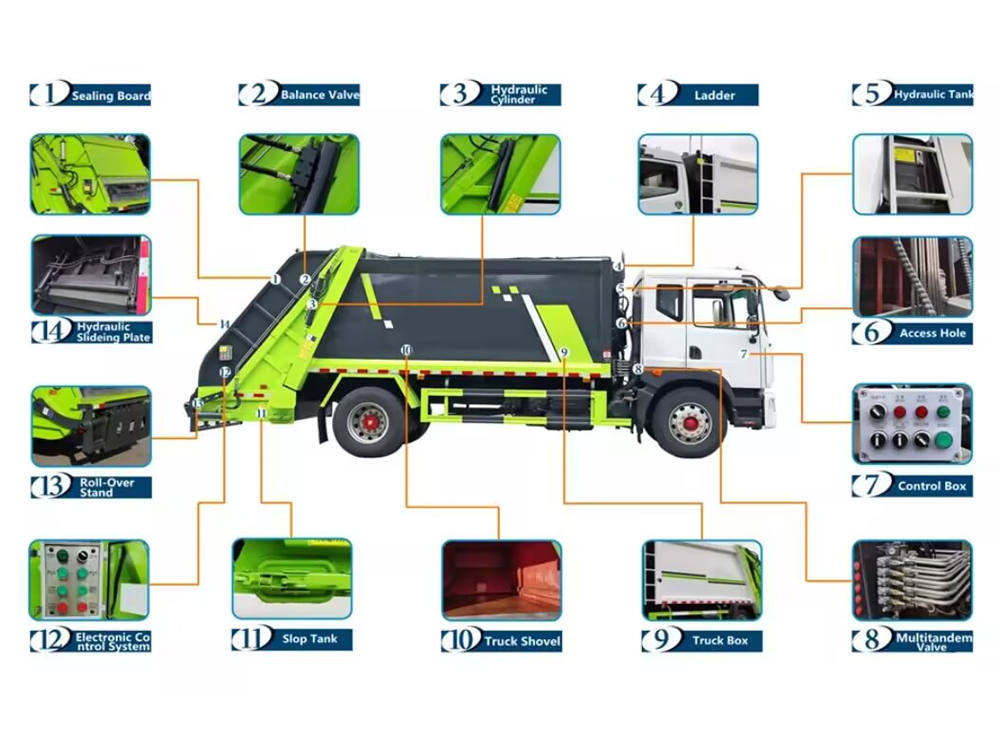

Isuzu FTR garbage compactor truck is a special sanitation truck used for garbage collection and transportation. It adopts electromechanical and hydraulic integration technology and adopts a combined mechanical, electrical and hydraulic automatic control system.

Isuzu FTR garbage compactor truck(QL1160VMFRY) uses special devices such as carriages, loaders, and push shovels to load, crush or flatten garbage, and forcefully fill it. Finally, the garbage is compacted and squeezed into the carriage, and transported to the destination for automatic push and unloading. The outstanding features of Isuzu FTR garbage compactor truck are: simple and efficient garbage collection method, repeated compression function, high compression ratio, large loading mass, automated operation, good power and environmental protection, and high vehicle utilization efficiency.

The mechanical, electrical and hydraulic combined automatic control system of the Isuzu FTR garbage compactor truck(QL1160VMFRY) is mainly composed of controllers, sensors, actuators and hydraulic systems. The controller is the core component of the system, responsible for monitoring the information fed back by the sensor and controlling the movement of the actuator according to the preset control strategy. The sensor is used to sense the status of the compressed garbage truck, such as the filling status of the garbage bin, the position of the compression device, etc. The actuator drives the hydraulic system according to the instructions of the controller to realize the automated operation of the Isuzu FTR garbage compactor truck. The hydraulic system is responsible for providing sufficient pressure and flow to drive the movement of the actuator.

|

ISUZU FTR 205hp 16cbm garbage compactor truck(QL1160VMFRY) parameters for reference |

||

|

Chassis |

||

|

Chassis model number |

ISUZU FVR chassis(QL1160VMFRY) |

|

|

Cabin |

Brand: ISUZU |

|

|

|

FTR row half cab, 4x2 left hand drive |

|

|

|

3 seats, with air conditioner, USB connector radio |

|

|

Vehicle Main Dimensions |

Overall dimensions (L x W x H) mm: 8150X2500X3250mm |

|

|

|

Wheel base: 4500 (mm) |

|

|

|

Overhang (front/rear):1335 / 1735 (mm) |

|

|

|

Approach angle: 15° |

|

|

|

Departure angle: 17° |

|

|

Weight in KGS |

Curb Weight:9800kg |

|

|

Max. driving speed(km/h) |

105 | |

|

Engine |

Brand |

ISUZU |

|

|

Model |

4HK1 , EURO 5 |

|

|

Emission |

5.193L |

|

|

Horse Power(HP) |

205HP |

|

Gearbox |

ISUZU MLD, 6 Forwards gear & 1 reverse gear |

|

|

Tire |

1000R20, 6 pcs+1 spare tire |

|

|

Axle |

Front axles 6.3t, rear axle13t |

|

|

Garbage box parameters |

||

|

Volume |

16 m3 |

|

|

Material |

Carbon steel and high tensile steel |

|

|

Standard equipment |

1. Dustbin volume: 16 m³ 2. hydraulic control device |

|

1. Mechanical part

The mechanical part of the Isuzu FTR refuse compactor truck is the core part of the entire system. This part mainly includes the compression device, transmission device and loading device of the garbage truck. In this system, the compression device plays the role of compactor garbage, compressing the garbage from its original state into a smaller volume, thereby reducing the number of garbage disposals of the Isuzu FTR refuse compactor truck. The transmission device is responsible for transmitting the engine's power to various mechanical components to ensure the normal operation of the system. The loading device is responsible for loading garbage into the garbage truck.

2. Electrical part

The electrical part of the Isuzu FTR waste compactor truck(QL1160VMFRY)mainly includes electronic control systems and sensors. The electronic control system is responsible for controlling the operation of the entire system, including the start and stop control of the transmission device, compression device, and the coordination of various equipment. The sensor is responsible for monitoring the working status of the garbage truck, such as the pressure, temperature and other parameters of the compression device, to ensure the safe operation of the Isuzu FTR waste compactor truck.

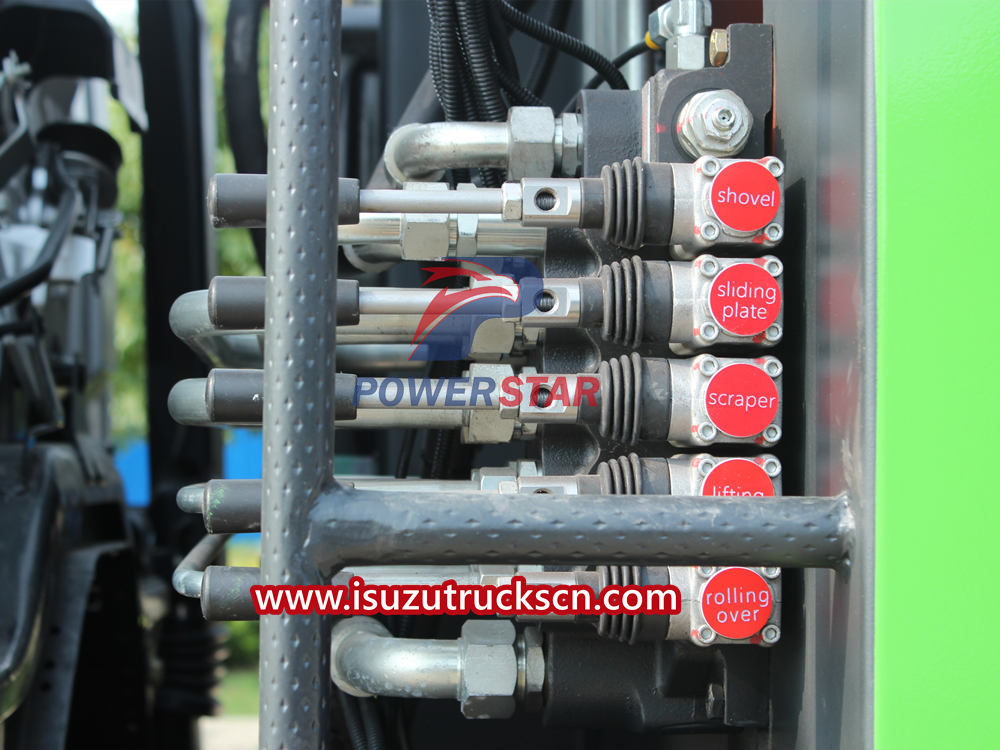

3. Hydraulic part

The hydraulic part is an important part of the Isuzu FTR garbage compactor truck(QL1160VMFRY). The hydraulic system mainly includes hydraulic pumps, valves, cylinders and other components. The hydraulic pump is responsible for extracting hydraulic oil from the tank and sending it to the actuator, providing pressure and flow to the hydraulic system. The valve is responsible for controlling the flow direction of oil in the hydraulic system and controlling the operation of each actuator. The oil cylinder is responsible for realizing the mechanical work of the hydraulic system, converting the pressure of the hydraulic oil into mechanical force, and completing the compression of garbage.

4. Automatic control part

The Isuzu FTR dumpster compactor truck mechanical, electrical and hydraulic combined automatic control system realizes fully automated control of the garbage truck. Through the monitoring of various sensors, the control of the electrical system and the drive of the hydraulic system, the entire system can realize automatic loading, automatic compression and automatic unloading of garbage, reducing manual operations and improving the work efficiency of the Isuzu FTR dumpster compactor truck. At the same time, automated control can also reduce the interference of human factors, reduce the incidence of accidents, and improve the stability and safety of the system.

The Isuzu FTR garbage compactor truck(QL1160VMFRY)adopts a mechanical, electrical, and hydraulic combined automatic control system that can improve transportation efficiency, reduce environmental pollution, protect public health, and promote resource recycling. At the same time, the system has the characteristics of automated operation, which can improve the stability and safety of work and reduce the labor intensity of operators. Isuzu FTR garbage compactor truck can not only improve the efficiency of urban sanitation management, but also effectively improve the quality of urban environment, protect the health of citizens, and promote resource recycling. It is an indispensable and important tool for modern urban management.